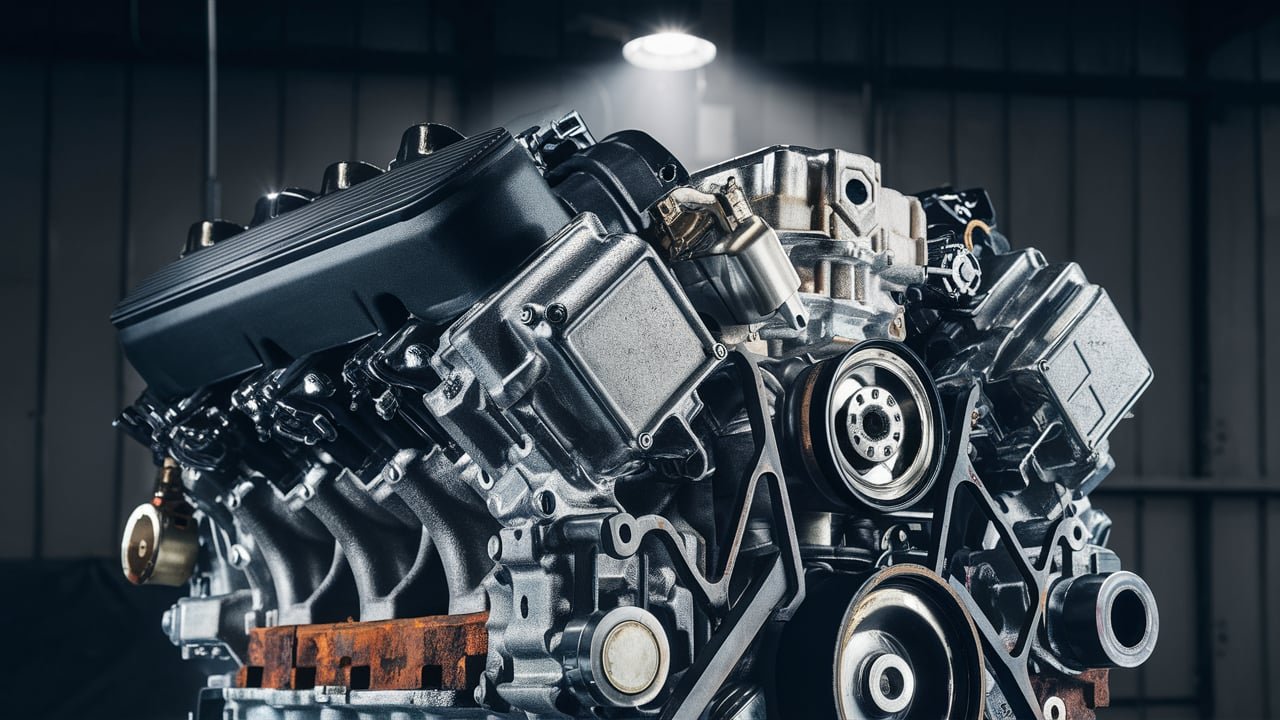

Exploring the Intricacies of a Car Engine Block

A car engine block, also known as a cylinder block, is the largest and heaviest part of the engine. It houses the major components where the combustion process takes place in a reciprocating engine. The block is typically made of aluminum alloy or cast iron and serves several critical functions:

Housing Cylinders and Components: The engine block contains the cylinders where pistons move up and down, fired by the fuel combustion process. It also holds the water cooling system, oil passages, and crankcase.

Heat Transfer: The metal construction of the block allows it to efficiently transmit heat from the combustion processes to the integral cooling system, which is essential for maintaining engine efficiency and preventing overheating.

Cooling System: The water jacket, also known as the cooling system, surrounds the cylinders and is supplied by the car’s radiator. This cooling system helps to prevent overheating and ensures the engine operates efficiently.

Oil Reservoir: The oil pan, located at the base of the engine block, provides a reservoir for the oil pump to draw from and supply the oil passages and moving parts.

Mounting Point: The engine block serves as a mounting point for various engine components, such as the alternator, water pump, power steering pump, and starter motor.

Common problems with engine blocks include external and internal coolant leaks, cracked cylinders, and porous blocks. Regular maintenance and inspection are crucial to ensure the engine block operates efficiently and prolongs its lifespan.

The unassuming car engine block, an unsung hero hidden beneath the hood, serves as the robust stronghold that encapsulates the intricate dance of power within an internal combustion engine. Housing critical components such as cylinders and crankshafts with unwavering fortitude, the engine block stands as a testament to engineering precision and structural mastery.

Beyond its mere physical presence lies a world of intricacies waiting to be unraveled, offering automotive enthusiasts, mechanical engineers, and car aficionados alike a realm teeming with meticulous design and unparalleled functionality.

Crafted from resilient materials like cast iron or lightweight aluminum alloys, the engine block emerges as a bastion of strength while delicately balancing weight considerations for optimal performance.

But its significance stretches far beyond mere solidity; this cornerstone element orchestrates a symphony of movement within the engine’s heart, ensuring seamless coordination among pistons and combustion forces.

As the unsung guardian of cylinder alignment and temperature regulation, the engine block silently performs its duty in providing unwavering support to every mechanical cog in the intricate machinery that propels us forward. Delve deeper into the inner workings of this mechanical marvel, where every curve and contour plays a crucial role in igniting our collective fascination with automotive technology.

Understanding the Design of Engine Blocks.

Engine blocks serve as the foundation of an internal combustion engine, and their design plays a crucial role in the overall performance and durability of a vehicle. When it comes to materials used in manufacturing engine blocks, cast iron and aluminum alloys are two common choices.

Cast iron offers excellent strength and durability, making it ideal for heavy-duty applications where reliability is paramount. On the other hand, aluminum alloys are lighter in weight, allowing for improved fuel efficiency without compromising structural integrity. Manufacturers carefully select these materials based on factors such as engine size, intended use, and cost considerations.

A well-designed cooling system within the engine block is essential to maintain optimal operating temperatures and prevent overheating. Engine blocks feature intricate passages and channels through which coolant flows to absorb excess heat generated during combustion.

By optimizing the cooling system design, manufacturers ensure efficient heat dissipation across critical components like cylinders, pistons, and crankshafts. Without proper cooling mechanisms, engines are at risk of seizing up or sustaining damage due to excessive heat buildup—a testament to the fundamental importance of effective thermal management systems within engine blocks.

Manufacturers go to great lengths to optimize the design of engine blocks for multiple purposes beyond mere structural support. Enhancing strength while minimizing weight is a delicate balance achieved through precision engineering techniques.

Lightweight yet robust designs contribute to better fuel efficiency and vehicle performance while reducing emissions. Moreover, efficient heat dissipation not only enhances engine longevity but also allows for sustained power output under demanding conditions.

By prioritizing these aspects in their designs, engineers ensure that modern engine blocks meet stringent performance requirements while delivering exceptional reliability on the road or track.

Internal Components of an Engine Block.

Within the intricate structure of a car engine block lies a crucial component: the cylinders. Cylinders are where the magic of combustion occurs, transforming fuel into energy that powers the vehicle. These cylindrical cavities house pistons that move up and down during the combustion cycle, generating the force needed to drive the vehicle forward.

The layout of cylinders in an engine block varies depending on the engine’s configuration—be it inline, V-shaped, flat, or rotary—an aspect that significantly impacts performance and efficiency.

Cylinder bores play a vital role within an engine block by providing a precisely machined space for pistons to move smoothly without friction. Proper clearance between cylinder walls and pistons is essential for optimal performance and longevity of the engine.

Any deviation from the specified tolerances can result in reduced power output, increased wear on components, or even catastrophic failure. Engineers meticulously design these dimensions to ensure efficient operation and minimal frictional losses within the engine.

Modern engine blocks incorporate sophisticated features like water jackets and oil galleries to maintain optimal operating conditions. Water jackets surround cylinders to facilitate the flow of coolant for heat dissipation, preventing overheating during intense combustion processes.

Similarly, oil galleries distribute lubrication throughout critical components such as pistons and crankshafts, ensuring smooth movement and reducing wear over time. These integrated systems work harmoniously to regulate temperature levels and provide necessary lubrication for longevity and efficiency in engine performance.

In essence, understanding how cylinders, cylinder bores, water jackets, and oil galleries function within an engine block unveils the complexity behind what drives our vehicles forward. The synergy between these internal components highlights the precision engineering required to create reliable power plants that propel automotive innovation further.

Maintaining these components at their optimal operating conditions through regular inspections and maintenance safeguards against premature wear or failures while maximizing both performance and longevity.

Common Issues and Maintenance Practices.

Engine blocks, like any other component in a car, are susceptible to various issues that can impact the overall performance of the vehicle. One common problem faced by engine blocks is the development of cracks, often caused by overheating or sudden temperature changes.

These cracks can compromise the structural integrity of the block and lead to coolant leaks or oil seepage, which can further exacerbate the situation. To prevent such issues, regular maintenance practices are essential.

Maintenance tips play a crucial role in ensuring the longevity and functionality of engine blocks. Routine coolant checks are vital to detect any leaks or abnormalities in the cooling system that could potentially harm the engine block.

Furthermore, using high-quality oil can help reduce friction between moving parts within the block, ultimately minimizing wear and tear. Monitoring temperature gauges regularly allows early detection of overheating problems, enabling prompt intervention before major damage occurs.

In cases where engine blocks develop cracks or other significant issues, it is essential to consider repair options promptly. Welding cracks can be a viable solution for minor damages if performed by a skilled professional following industry standards.

For more severe cases like damaged cylinder walls, installing reinforced sleeves may be necessary to restore optimal functionality without replacing the entire block. By addressing these common issues through effective maintenance practices and timely repairs, car owners can prolong the lifespan of their engine blocks and maintain peak performance levels in their vehicles.

Innovations in Engine Block Technology.

The evolution of engine block technology has seen remarkable advancements geared towards enhancing performance and efficiency. One notable innovation is the integration of carbon fiber composites into engine block materials.

The use of carbon fiber composites not only offers exceptional strength but also significantly reduces weight, contributing to improved overall vehicle performance by enhancing power-to-weight ratios. These advanced materials are particularly advantageous in high-performance engines where every pound saved translates into increased speed and agility.

Another key development in engine block technology revolves around modular designs. Automakers are increasingly adopting modular approaches that allow for easier customization and upgrades without the need for extensive modifications.

By incorporating standardized components that can be easily swapped out or upgraded, these modular engine blocks enable more efficient maintenance processes and facilitate future technological enhancements without requiring a complete overhaul of the entire system.

This flexibility not only simplifies manufacturing processes but also benefits car enthusiasts and technicians who seek to tweak or upgrade their vehicles.

Furthermore, the utilization of 3D printing technology has revolutionized the prototyping and production of complex geometries within engine blocks. Manufacturers can now create intricate designs with precision and accuracy, allowing for optimized internal components that enhance performance and efficiency.

The ability to rapidly prototype different configurations through 3D printing enables engineers to test various layouts quickly, leading to innovations in combustion chamber design, coolant flow optimization, and overall structural integrity within engine blocks.

This cutting-edge technology paves the way for future advancements in engine block design, pushing the boundaries of what is achievable in terms of performance and functionality in automotive engineering.

Environmental Impact and Future Trends.

In the realm of automotive engineering, environmental consciousness is steering the development of sustainable practices in engine block production. With a rising focus on reducing carbon footprints, manufacturers are now embracing eco-friendly initiatives by opting for materials with lower environmental impact.

This shift involves sourcing sustainable materials like recycled aluminum or utilizing greener manufacturing processes to minimize waste and energy consumption during production. By adopting these measures, the automotive industry aims to reduce its ecological footprint while maintaining high standards of performance and durability in engine blocks.

Looking ahead to future trends, the integration of hybrid engines represents a significant advancement in engine block technology. Hybrid vehicles that combine traditional combustion engines with electric powertrains are gaining traction due to their improved fuel efficiency and lower emissions.

Within next-generation engine blocks, engineers are exploring innovative designs that seamlessly accommodate both power sources while optimizing space and weight distribution. This disruptive shift towards hybridization not only enhances overall vehicle performance but also sets a new standard for sustainability by reducing reliance on fossil fuels.

However, as the automotive landscape evolves towards more environmentally friendly solutions, challenges arise in adapting existing infrastructure to accommodate these cutting-edge technologies effectively. Ensuring compatibility between conventional components and modern advancements necessitates meticulous planning and coordination across various engineering disciplines.

Additionally, enhancing overall efficiency amidst this transition requires reevaluating manufacturing processes, supply chains, and service networks to align with the demands of eco-conscious consumers without compromising on quality or performance standards.

As the industry navigates this transformative period, collaboration between stakeholders becomes crucial for streamlining operations and capitalizing on the vast potential that sustainable engine block technologies offer for a cleaner automotive future.

How Does the Engine Block Contribute to Engine Efficiency?

The engine block plays a crucial role in maintaining engine efficiency by providing a robust and efficient cooling system. Here are some ways it contributes:

- Heat Transfer: The engine block’s metal construction allows it to efficiently transfer heat from the combustion process to the cooling system. This ensures that the engine operates within a safe temperature range, preventing overheating and damage to critical components.

- Cooling System: The water jacket, integrated into the engine block, helps to dissipate heat generated during combustion. This cooling system is essential for maintaining engine efficiency and preventing overheating.

- Reduced Friction: The engine block’s design and material choice help to minimize friction between moving parts, reducing energy loss and increasing overall engine efficiency.

- Improved Lubrication: The engine block’s oil passages and oil pan ensure proper lubrication of moving parts, reducing friction and wear, and maintaining engine efficiency.

What Materials Are Commonly Used for Engine Blocks and Why?

Engine blocks are typically made from aluminum alloy or cast iron due to their unique properties:

- Aluminum Alloy:

- Lightweight: Aluminum alloy engine blocks are significantly lighter than cast iron blocks, reducing overall engine weight and improving fuel efficiency.

- Corrosion Resistance: Aluminum alloy is more resistant to corrosion than cast iron, reducing the risk of damage from moisture and improving durability.

- Thermal Conductivity: Aluminum alloy has high thermal conductivity, allowing it to efficiently transfer heat from the combustion process to the cooling system.

- Cast Iron:

- Strength and Durability: Cast iron engine blocks are known for their exceptional strength and durability, making them suitable for high-performance and heavy-duty applications.

- Thermal Mass: Cast iron has high thermal mass, which helps to absorb and dissipate heat generated during combustion, improving engine efficiency.

- Cost-Effective: Cast iron engine blocks are generally less expensive to produce than aluminum alloy blocks, making them a cost-effective option for many applications.

How Does the Water Jacket in an Engine Block Work?

The water jacket in an engine block is a critical component of the cooling system. Here’s how it works:

- Water Flow: Coolant flows through the water jacket, which is typically a series of passages and channels within the engine block.

- Heat Transfer: As the coolant flows through the water jacket, it absorbs heat generated during combustion from the cylinders and engine components.

- Coolant Circulation: The cooled coolant is then circulated back to the radiator, where it is cooled further before being re-circulated through the engine block.

- Temperature Regulation: The water jacket helps to regulate engine temperature by maintaining a consistent temperature range. This ensures that the engine operates within a safe temperature range, preventing overheating and damage to critical components.

By understanding how the engine block contributes to engine efficiency, the materials used for engine blocks, and how the water jacket works, you can better appreciate the importance of proper engine maintenance and the role of the engine block in ensuring optimal engine performance.

Concluding Insights on Car Engine Blocks.

In conclusion, delving into the intricacies of a car engine block reveals a crucial element in the heart of an internal combustion engine. From the meticulous design considerations to the selection of materials and integration of advanced technologies, the engine block stands as a testament to engineering excellence.

As automotive enthusiasts, mechanical engineers, car aficionados, and auto technicians continue to unravel the complexities within this critical component, a deeper appreciation for its role in power generation and vehicle performance emerges.

The journey through understanding engine blocks showcases a blend of tradition and innovation, where time-tested practices merge with cutting-edge advancements to push the boundaries of automotive engineering.

With a keen eye on environmental sustainability and future trends shaping the automotive industry, it is evident that engine blocks are not just inert structures but dynamic pieces evolving with each technological stride.

As we peer into the horizon of automotive evolution, one thing remains certain – the legacy of precision engineering embodied by the intricate design and functionality of a car engine block will continue to drive progress in mobility for generations to come.