Demystifying Car Engine Cylinders: A Comprehensive Guide

Understanding Car Engine Cylinders

Car engine cylinders are the fundamental components responsible for converting chemical energy from fuel into mechanical energy. This comprehensive guide will break down the key aspects of engine cylinders, including their structure, function, and importance in the overall engine operation.

Structure of Car Engine Cylinders.

A car engine cylinder typically consists of the following components:

- Cylinder Block: This is the main structural component of the engine, housing multiple cylinders. It provides a sturdy foundation for the engine’s operation.

- Cylinder Head: Mounted atop the cylinder block, the cylinder head forms the top of the combustion chamber. It contains critical parts like valve rockers, pushrods, ports for spark plugs and injectors, and passageways for air, coolant, and oil.

- Pistons and Crankshaft: Pistons travel up and down inside the cylinders, sealed against the cylinder walls with piston rings. The crankshaft, connected to the pistons by connecting rods, converts their linear motion into rotational energy.

Function of Car Engine Cylinders.

The primary function of engine cylinders is to facilitate the four-stroke cycle:

- Intake Stroke: The piston moves down, and the intake valve opens, allowing a precise mixture of fuel and air to enter the cylinder.

- Compression Stroke: The piston moves back up, compressing the fuel-air mixture. This compression is crucial for powerful and efficient combustion.

- Power Stroke: With the mixture compressed, the spark plug ignites it, causing an explosion. This force pushes the piston down, turning the crankshaft and generating power.

- Exhaust Stroke: As the piston rises again, the exhaust valve opens, allowing the gases from the burned air and fuel to be pushed out of the cylinder.

Importance of Car Engine Cylinders.

Engine cylinders play a vital role in the overall engine operation and performance. They:

- Convert Chemical Energy: Cylinders convert the chemical energy from fuel into mechanical energy, which powers the vehicle.

- Determine Engine Performance: The number and size of cylinders, as well as their configuration, significantly impact an engine’s power output, torque, and efficiency.

- Influence Fuel Efficiency: Proper cylinder design and operation can improve fuel efficiency by optimizing combustion and reducing waste.

- Affect Emissions: Well-maintained cylinders can help reduce emissions by ensuring efficient combustion and minimizing waste gases.

Troubleshooting and Maintenance.

Regular maintenance and troubleshooting are crucial to ensure optimal engine performance and longevity. Key tasks include:

- Oil Changes: Regular oil changes help keep moving parts lubricated, reducing friction and wear.

- Coolant Checks: Routinely check coolant levels and inspect hoses and belts to prevent overheating.

- Air Filter Replacements: Regularly replace air filters to ensure optimal airflow, combustion efficiency, and fuel economy.

- Fuel System Maintenance: Clean or replace fuel filters and inspect fuel injectors to prevent clogs and ensure efficient combustion.

Car engine cylinders are the heart of the engine, converting chemical energy into mechanical energy. Understanding their structure, function, and importance in the overall engine operation is crucial for optimal performance and longevity. By following proper maintenance and troubleshooting practices, you can ensure your engine runs smoothly and efficiently.

In the intricate symphony of mechanized marvel that propels our vehicles forward, one key player takes center stage: the car engine cylinder. Defined as the fundamental locus where combustion orchestrates its fiery ballet within an internal combustion engine, these cylindrical powerhouses hold the essence of automotive potency.

Understanding the enigmatic inner workings of these cylinders is not merely a pursuit reserved for industry insiders but a crucial quest for automotive enthusiasts, mechanics, and budding engineering minds alike.

Dive into the depths of automotive engineering where each piston stroke sparks ingenuity and every compression ratio defines performance thresholds. Unravel the mysteries behind the structural prowess of engine cylinders—from their resilient materials to precision-engineered components such as pistons and valves—guiding you towards a landscape where theoretical mastery meets practical finesse.

Embark on a journey through the heart of machinery as we dissect cylinder configurations with surgical precision and explore how subtle design variations impact efficiency and power output in ways both nuanced and profound. Join us in demystifying the very crucible of vehicular propulsion that sets enthusiasts’ hearts ablaze, mechanics’ hands diligently tuning, and future engineers’ curiosity aflame.

The Structure of Car Engine Cylinders.

Car engine cylinders stand as the heart of internal combustion engines, encompassing a robust design essential for power generation. These cylinders typically exhibit a cylindrical shape, which not only maximizes efficiency in containing and controlling high-pressure gases but also facilitates straightforward manufacturing processes.

The materials employed in crafting engine cylinders are crucial to withstand extreme temperatures and pressures during operation. Commonly, engine cylinders are constructed from cast iron or aluminum alloys, each offering distinct advantages ranging from durability to heat dissipation properties.

Within the cylinder itself lies an intricate network of components that harmoniously work together to ensure streamlined functionality. Pistons, acting as movable seals within the cylinder bore, oscillate up and down when combusting fuel-air mixtures. Piston rings form a barrier between the piston and cylinder walls, preventing gas leakage and ensuring efficient compression.

Engine valves dictate the intake of air-fuel mixtures and expulsion of exhaust gases with precise timing, crucial for optimal engine performance. Moreover, maintaining these components’ integrity necessitates meticulous cylinder honing processes to guarantee smooth surfaces for proper piston movements and sealing capabilities.

Cylinder honing plays a pivotal role in sustaining top-notch engine performance over time. This process involves refining the interior surface finish of the cylinder bore to minimize friction between pistons and walls while enhancing oil retention properties.

By eliminating imperfections or irregularities within the cylinder surface through honing techniques, such as plateau finishing, mechanics can achieve superior lubrication distribution and reduced wear on critical engine parts.

Consequently, regular maintenance involving cylinder honing becomes indispensable for mitigating issues like piston scuffing or accelerated wear – ultimately ensuring prolonged engine lifespan and sustained operational efficiency.

Types of Engine Cylinders.

In the realm of car engine cylinders, various configurations exist, each with its own set of characteristics and applications. Inline engines are known for their space efficiency, where all cylinders are aligned in a row, typically found in compact vehicles like sedans.

On the other hand, V-shaped engines offer a more compact design by angling the cylinders into a V formation, aiding in better weight distribution and lower center of gravity—commonly seen in sports cars and luxury vehicles for enhanced performance.

Additionally, flat or boxer engines have horizontally opposed pistons that cancel out secondary forces for smoother operation while creating a unique sound profile favored by brands like Porsche.

When comparing single-cylinder engines to multi-cylinder designs, efficiency and power output become key considerations. Single-cylinder engines are often found in motorcycles and small machinery due to their simplicity and cost-effectiveness; however, they lack the power and balance offered by multi-cylinder setups.

Multi-cylinder configurations like inline-4s or V8s distribute power more evenly throughout the crankshaft rotation cycle, resulting in smoother operation and enhanced torque delivery crucial for high-performance vehicles or heavy-duty applications.

Each type of engine cylinder layout presents distinct advantages and disadvantages worth noting. For instance, inline layouts are revered for their simplicity in maintenance tasks like accessing spark plugs or exhaust systems easily.

Conversely, V-shaped configurations offer superior balancing properties due to paired cylinders alleviating vibration concerns but may pose challenges in terms of packaging constraints within the engine bay. Understanding these nuances can guide automotive enthusiasts, mechanics, and engineering students towards making informed decisions when selecting engines based on their intended use cases.

Cylinder displacement.

Cylinder displacement plays a pivotal role in defining an engine’s capabilities. It refers to the total volume swept by all the pistons within the cylinders during one complete cycle of operation. In simpler terms, it indicates how much air-fuel mixture can be drawn into all the engine cylinders when they operate together.

Engines with larger cylinder displacements tend to generate more power due to their ability to burn more fuel and produce stronger combustion forces. For instance, a high-performance V8 engine with a displacement of 6.2 liters will typically deliver greater horsepower and torque compared to a compact 1.5-liter inline-four engine commonly found in economy cars.

Bore and stroke measurements are integral parameters that directly impact an engine’s performance characteristics. The bore represents the diameter of the cylinder, while the stroke signifies the distance traveled by the piston inside the cylinder from top dead center (TDC) to bottom dead center (BDC).

These measurements influence torque production; a longer stroke tends to enhance low-end torque, which is beneficial for towing or off-road applications, while a bigger bore diameter often leads to higher peak power outputs best suited for performance-oriented driving scenarios. Engine builders and designers must carefully balance these dimensions based on the intended purpose of the vehicle.

The bore/stroke ratio reflects how these two critical measurements interact within an engine design. This ratio affects factors such as engine smoothness, responsiveness, and overall efficiency. An engine with a square bore/stroke configuration (equal values) may exhibit different characteristics compared to one with an undersquare or oversquare layout.

For example, a motorcycle built for high-revving capabilities might feature an oversquare design with a larger bore relative to stroke length for increased breathing capacity at higher RPMs, optimizing horsepower output. Understanding and selecting the right bore/stroke ratio tailored to specific engine applications is crucial for achieving optimal performance results across various driving conditions and requirements.

Cylinder Compression Ratio.

Understanding the cylinder compression ratio is fundamental for grasping the intricacies of engine performance. The compression ratio, defined as the total volume of a combustion chamber when the piston is at bottom dead center (BDC) versus top dead center (TDC), directly influences both fuel efficiency and power output.

A higher compression ratio leads to increased thermal efficiency, extracting more mechanical energy from fuel combustion. For instance, an engine with a 10:1 compression ratio compresses the air-fuel mixture to \(\frac{1}{10}\) of its original volume just before ignition.

Various factors come into play when adjusting the compression ratio, impacting overall engine behavior. Changes in piston design, cylinder head shape, or gasket thickness can alter the compression ratio substantially.

These adjustments influence not only power and efficiency but also engine knock susceptibility and emissions characteristics. For instance, decreasing the compression ratio can reduce knocking tendencies when using lower octane fuels in high-performance engines.

Calculating the compression ratio involves precise measurements of cylinder volumes at different positions during the engine cycle. By obtaining accurate values for combustion chamber volume at BDC and TDC, calculating the static compression ratio becomes feasible.

This calculation helps engineers optimize engine designs for specific performance requirements such as maximizing power delivery or enhancing fuel economy based on how efficiently they manage air-fuel mixture combustion within each cylinder throughout operation.

Cooling Systems for Engine Cylinders.

When it comes to ensuring optimal performance and longevity of car engine cylinders, an often-overlooked yet critical aspect is the cooling system in place. Two primary methods employed in managing cylinder temperatures are air-cooled and liquid-cooled systems.

Air-cooled setups rely on the natural airflow around the engine to dissipate heat, commonly found in older models or performance-oriented motorcycles like the iconic BMW R nineT with its exposed cylinder heads.

On the other hand, liquid-cooled systems utilize a network of coolant jackets, water pumps, thermostats, and radiators to regulate temperatures efficiently, as seen in modern vehicles like the Subaru WRX STI.

In air-cooled configurations, metal fins strategically placed on the exterior of cylinders aid in dispersing heat into the surrounding environment. These fins increase surface area exposure to air for more effective cooling. In contrast, liquid-cooled engines circulate a specialized coolant mixture through passages within the engine block and head.

This method allows for more precise temperature control and consistent operating conditions regardless of external factors like ambient temperature variations. The intricate balance maintained by these cooling systems is paramount to prevent overheating that could lead to catastrophic damage such as warped cylinder heads or seized pistons.

Regular maintenance of cooling systems.

Regular maintenance of cooling systems is imperative for preventing potential risks associated with overheating. Neglecting proper cooling system upkeep can result in reduced engine efficiency and premature wear on vital components like cylinder walls and piston rings.

By ensuring that cooling fins are clean and unobstructed or monitoring coolant levels regularly in a liquid-cooled setup, enthusiasts and mechanics alike can optimize engine performance while prolonging the lifespan of essential parts. Remember, maintaining proper cooling not only preserves your engine’s health but also contributes significantly to overall vehicle reliability and operational safety.

In essence, whether you own a classic air-cooled Porsche 911 Carrera or a cutting-edge liquid-cooled Tesla Model S Plaid, understanding the nuances of different cooling systems is pivotal in safeguarding your engine’s well-being.

By grasping how cooling methods impact cylinder temperatures and consequently overall vehicle operation, enthusiasts can make informed decisions regarding maintenance practices tailored to their specific vehicle type.

With proper attention given to maintaining optimal operating temperatures through efficient cooling solutions, you pave the way for a seamless driving experience while extending the life expectancy of your cherished car’s heart—the engine cylinders.

Performance Modifications for Engine Cylinders.

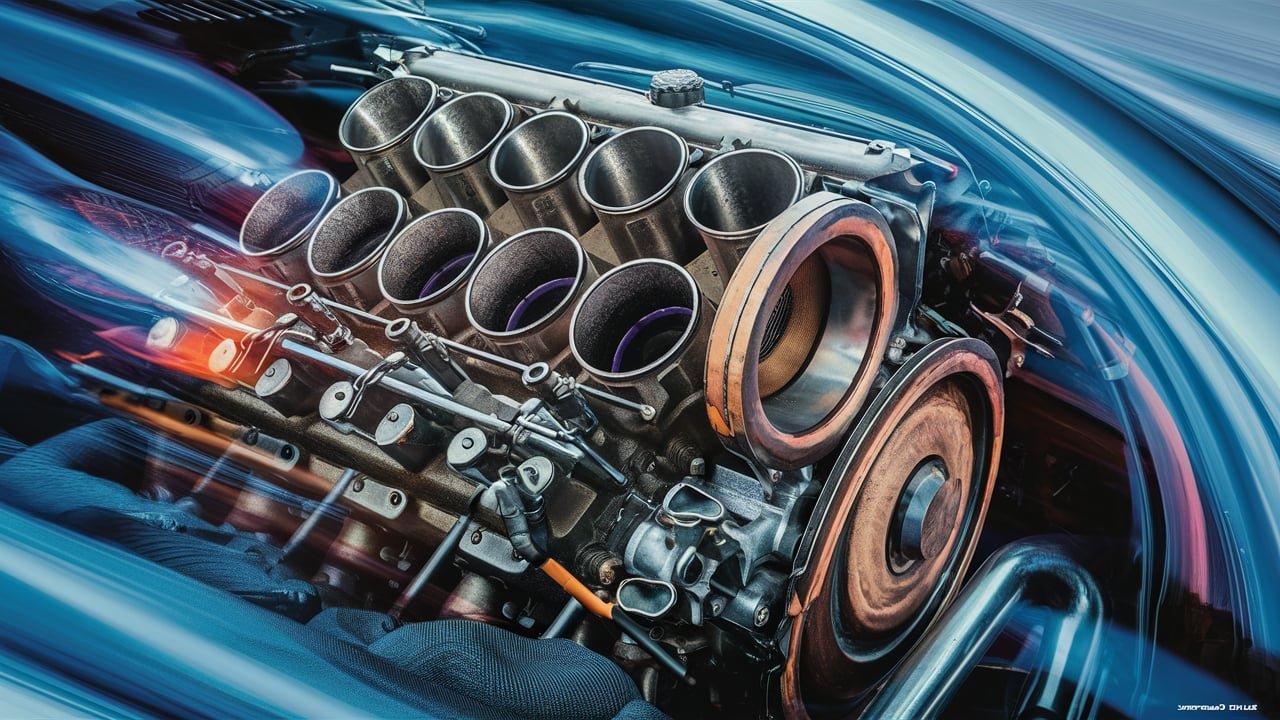

When it comes to boosting the performance of a car engine, modifications to the cylinders play a pivotal role. Common upgrades like porting, which involves reshaping and smoothing the intake and exhaust ports within the cylinder head, can lead to improved airflow efficiency.

Polishing these surfaces further eliminates any roughness that may hinder optimal air and fuel mixture flow. Boring out cylinders refers to increasing their diameter for enhanced displacement, allowing more air and fuel into the chamber for combustion.

Similarly, stroking involves lengthening the piston stroke within the cylinder to increase torque output, especially beneficial in high-performance applications where quick acceleration is key.

Camshaft selection is another critical aspect when aiming for enhanced performance through cylinder modifications. The camshaft dictates valve timing and duration, influencing how effectively air enters and exits the combustion chamber. Matching the camshaft profile with intended RPM ranges can greatly impact volumetric efficiency – maximizing power output throughout the engine’s operating range.

In terms of aftermarket parts that aid in improving airflow or increasing displacement, consider upgrades like high-flow intake manifolds, performance headers, or even larger throttle bodies.

These components enhance air delivery into cylinders while optimizing exhaust gas scavenging for better engine breathing dynamics. By increasing airflow efficiency without sacrificing fuel atomization quality, these parts contribute to an overall uptick in engine power delivery and responsiveness.

Illustrating these concepts with a real-world scenario: imagine a classic muscle car undergoing performance enhancements by enlarging its cylinder bores alongside installing a high-lift camshaft that’s finely tuned with free-flowing exhaust headers.

These modifications collectively aim to bolster not just horsepower figures but also improve throttle response and overall drivability. Whether on a drag strip or a twisty mountain road, these enhancements showcase how strategic cylinder modifications can transform an average performing engine into a powerhouse of exhilaration on wheels.

Maintenance Tips for Engine Cylinders.

Regular maintenance of engine cylinders is crucial to ensure the longevity and optimal performance of your vehicle’s engine. Here are some essential tips to keep your car engine running smoothly:

1. **Check Cylinder Compression Levels**: Monitoring cylinder compression levels periodically is vital in detecting any potential issues early on. A drop in compression could indicate problems with the piston rings, valves, or cylinder walls. By addressing these issues promptly, you can prevent further damage and maintain consistent engine performance.

2. **Use Quality Lubricants**: Utilizing high-quality lubricants is key to reducing friction between pistons and cylinder walls. Proper lubrication helps minimize wear and tear, ensuring that the components move smoothly within the cylinders. This simple step can significantly extend the lifespan of your engine and improve overall efficiency.

3. **Diagnose Common Cylinder Issues**: Keeping an eye out for common cylinder issues like scoring or pitting can save you from costly repairs down the line. Scoring, which refers to grooves on the cylinder wall caused by debris or improper lubrication, can lead to reduced engine efficiency if left unaddressed. Pitting, on the other hand, involves small craters on the surface of the cylinders and may result from poor fuel quality or overheating.

By following these maintenance tips diligently, you can preserve the health of your engine cylinders and ensure smooth operation over time. Remember that preventive care is often more cost-effective than dealing with extensive repairs due to neglected maintenance practices. Regular inspections and proactive measures will help you avoid potential issues before they escalate into major concerns.

Future Trends in Car Engine Cylinder Technology.

As automotive engineering continues to push boundaries, future car engine cylinder technologies are poised for significant advancements. One exciting area of development is the integration of carbon nanotube coatings on cylinder surfaces.

These coatings offer enhanced wear resistance, reducing friction between moving parts and ultimately improving engine efficiency. By incorporating these advanced materials, engineers can extend the lifespan of cylinders and optimize performance over time.

Moreover, the evolution towards hybrid technologies and alternative fuels is reshaping the design considerations for engine cylinders. With the rise of electric vehicles and hybrids, there is a growing emphasis on integrating combustion engines with electric power sources.

This shift prompts innovation in cylinder technology to accommodate varying power requirements and fuel types effectively. Engineers are exploring ways to adapt cylinder designs to meet the demands of diverse propulsion systems without compromising performance or reliability.

In line with environmental concerns and fuel efficiency goals, downsizing trends are influencing future cylinder designs. Manufacturers are prioritizing smaller yet more efficient combustion chambers within cylinders to enhance thermal efficiency and reduce emissions.

This trend aligns with the industry’s focus on developing greener solutions without compromising power output. By optimizing the size and shape of combustion chambers within cylinders, engineers can achieve a balance between performance and sustainability in next-generation vehicles.

In conclusion, as we look ahead to the future of car engine cylinder technology, it is evident that continuous innovation will drive substantial enhancements in vehicle performance and sustainability.

From carbon nanotube coatings for improved durability to tailored designs for hybrid applications and downsized combustion chambers for efficiency gains, these future trends represent a dynamic shift toward more advanced and eco-friendly automotive solutions.

Embracing these innovations will not only revolutionize how engines operate but also pave the way for a more sustainable future in transportation technology.

Conclusion.

In conclusion, car engine cylinders represent the heart of internal combustion engines, serving as the core components where fuel is ignited to generate power. Understanding the intricacies of engine cylinders is paramount for automotive enthusiasts, mechanics, and engineering students alike.

From the structure and types of cylinders to critical measurements like displacement, bore/stroke ratio, and compression ratio, each parameter directly influences an engine’s efficiency and performance. Moreover, advancements in cooling systems, performance modifications, and maintenance practices continually shape the reliability and longevity of these vital elements within automotive systems.

By unraveling the complexities surrounding engine cylinders in this comprehensive guide, readers can now grasp the pivotal role these components play in powering vehicles across diverse automotive industries.

As technologies evolve and efficiency standards rise, a deep comprehension of engine cylinder functionality will remain crucial for driving innovation in vehicle design while enhancing overall performance standards. Armed with this knowledge, enthusiasts and professionals are better equipped to navigate the intricate world of car engines with precision and insight.