Unveiling the Essentials of a Car Engine Starter Motor

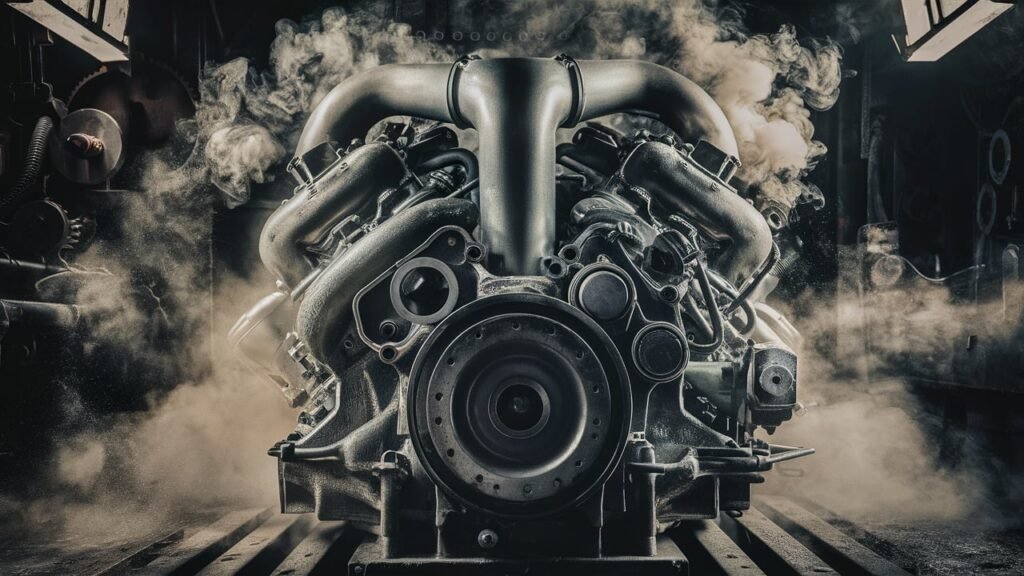

In the intricate dance of a car’s engine coming to life, there exists a silent yet crucial performer: the car engine starter motor. This unsung hero holds the key to kickstarting the heart of any internal combustion engine, providing the necessary impetus for automotive motion.

As we peel back the layers of this essential component, we uncover a world where electrical energy transforms seamlessly into mechanical force, setting in motion the symphony of pistons and gears that propel vehicles forward.

At its core, the car engine starter motor serves as the catalyst that ignites an engine into action. Its significance is deeply intertwined with every ignition cycle, where precision and reliability are paramount for seamless operation.

Understanding this vital component not only unravels the mechanics behind its function but sheds light on how pivotal it is in ensuring that every journey begins with a confident turn of the key.

Delving into the inner workings of this unassuming yet indispensable entity reveals a realm where inertia gives way to kinetic energy, heralding a harmonious crescendo as engines hum to life with each calculated revolution initiated by this masterful device.

Understanding the Basics of a Car Engine Starter Motor.

A car engine starter motor serves as a crucial component in the ignition process of an internal combustion engine. Its primary function lies in initiating the operation of the engine by rotating the crankshaft until the combustion process can self-sustain.

This rotational movement is essential for compressing air and fuel mixtures within the engine cylinders, enabling proper combustion and subsequent power generation. In essence, without a properly functioning starter motor, the entire vehicle’s propulsion system would be rendered non-operational.

The conversion of electrical energy into mechanical energy is at the core of how a starter motor operates. When prompted by turning the ignition key or pressing a start button, an electrical current is directed from the battery to the starter motor.

Through intricate mechanisms within the starter motor, this electrical energy is transformed into mechanical force, manifesting in rotational movement that engages with the engine’s flywheel or flexplate. This rotary motion provided by the starter motor kickstarts the engine’s cycle, allowing for fuel combustion to take place efficiently.

To simplify this process further, imagine if you will: just as one uses a key to wind a clock before it can tick away with precision, a starter motor winds up an automotive heart — its engine — before it can hum smoothly under its hood.

This synergy between electrical and mechanical systems underscores not just starting an engine but setting forth its rhythmic symphony of controlled explosions driving every vehicle forward on demand.

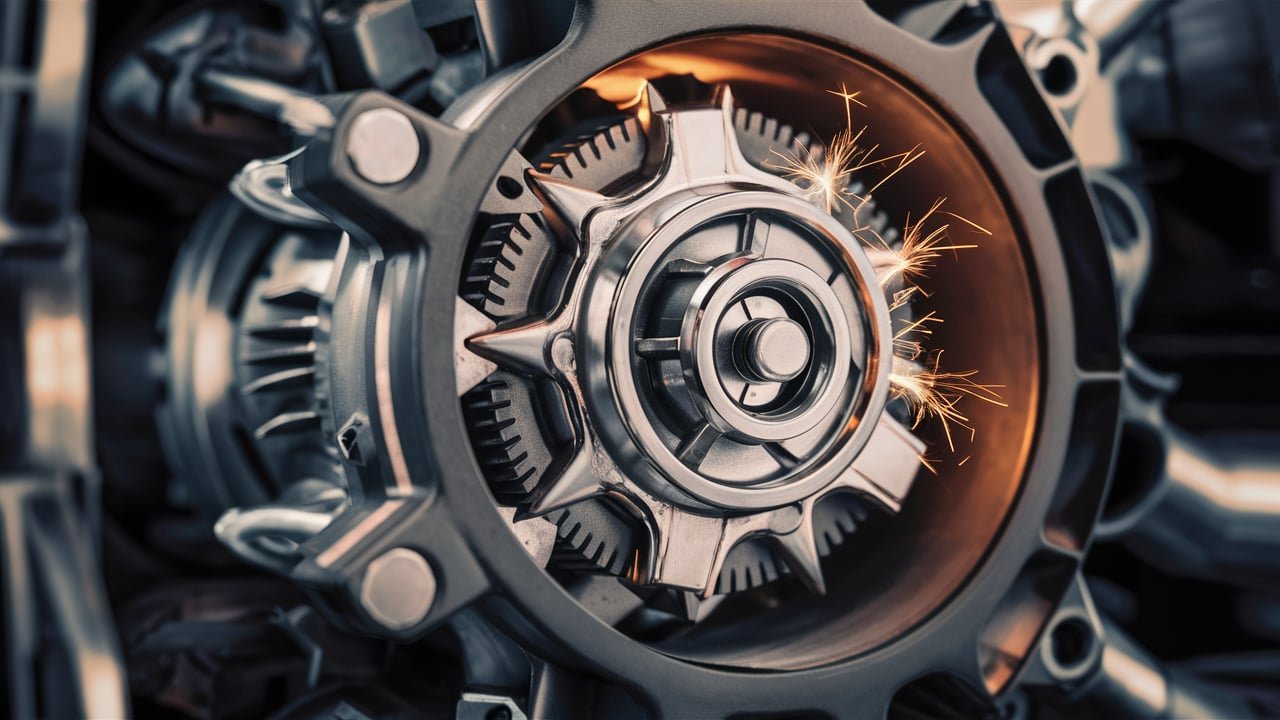

Key Components of a Starter Motor.

A starter motor is a vital component in the operation of an internal combustion engine, consisting of several key parts that work synchronously to initiate the engine’s movement. One essential element is the armature, a coil of wire wrapped around an iron core that rotates when an electric current passes through it.

The magnetic field generated by the armature interacts with the field windings, which are stationary coils of wire within the motor, creating mechanical force to spin the engine.

Complementing these components is the solenoid, acting as a switch to engage and disengage the starter from the engine’s flywheel ring gear. When electrical current flows through the solenoid, it pulls a plunger to connect the starter motor to the flywheel teeth for cranking.

Additionally, there is the drive gear, responsible for transferring motion from the starter motor to turn over the engine. As electricity powers up these various parts, they collaborate seamlessly like a symphony orchestra playing in perfect harmony.

Imagine your car’s engine as a slumbering giant waiting to be awakened – each component of the starter motor plays a distinct role in stirring it to life. Picture the armature as the conductor directing energy flow, while field windings provide background support harmonizing with solenoid and drive gear’s rhythmic movements.

Only when all sections perform their tasks precisely does this mechanical orchestra deliver its opening act: starting your vehicle smoothly with a satisfying purr. Understanding how these components work together highlights their significance in ensuring your daily automotive rituals unfold seamlessly.

Types of Starter Motors Used in Cars.

In the realm of automotive engineering, two primary types of starter motors are commonly employed to initiate the ignition process in internal combustion engines: direct-drive starters and gear-reduction starters. Direct-drive starters directly engage with the engine’s flywheel ring gear to crank the engine.

They are known for their simplicity and durability, making them a traditional choice in many vehicles. On the other hand, gear-reduction starters utilize an additional set of gears between the armature shaft and the pinion gear to reduce rotational speed and increase torque output. This design offers improved cranking power while being more compact compared to direct-drive counterparts.

Direct-drive starters are valued for their robustness and cost-effectiveness, ensuring reliable performance over long periods. However, they tend to draw higher currents during operation, potentially leading to quicker wear on electrical components.

In contrast, gear-reduction starters provide enhanced torque output with lower current consumption due to their gear reduction mechanism. Despite their efficiency advantages, gear-reduction starters generally come at a higher initial cost and may be more complex to service in certain vehicle configurations.

For example, in heavy-duty trucks where high-torque output is vital due to larger displacement engines, gear-reduction starters are often preferred for their ability to generate sufficient cranking power without overwhelming the electrical system.

Conversely, smaller passenger vehicles may opt for direct-drive starters for their simplicity and cost-efficiency since they require less torque to start the engine. Understanding the distinctions between these starter motor types allows automotive enthusiasts and technicians to make informed decisions based on specific vehicle requirements and operational demands.

Factors Affecting Starter Motor Performance.

Several factors play a crucial role in determining the performance of a car engine starter motor, from environmental conditions to the overall health of the vehicle’s electrical system. Temperature is a significant influencer; extreme cold can stiffen lubricants and increase friction, making it harder for the starter motor to turn over the engine.

On the other hand, high temperatures can lead to overheating of the components, reducing efficiency. Moreover, variations in voltage supply, whether due to a weak battery or faulty alternator, can directly impact the motor’s ability to function optimally. Ensuring a stable and adequate power supply is essential for consistent performance.

Engine load is another important consideration affecting starter motor performance. Heavier engines or those with mechanical issues requiring more torque to start can strain the starter motor, potentially leading to premature wear and reduced longevity.

Regular maintenance practices such as checking for loose connections, cleaning terminals, and properly securing ground cables are vital steps in ensuring optimal performance and extending the lifespan of the starter motor. Additionally, conducting periodic inspections of the battery condition and charging system helps preempt potential issues before they affect the starter motor’s operation.

By paying attention to these critical factors and implementing preventive measures through routine maintenance, car owners can significantly enhance their starter motor’s reliability and effectiveness.

Simple tasks like keeping battery terminals clean and tight can prevent voltage drop issues that may impede starting operations. Similarly, addressing minor engine problems promptly can alleviate unnecessary strain on the starter motor during each ignition cycle.

Prioritizing these factors not only sustains optimum functionality but also contributes to increased longevity of both the starter motor and associated components within the vehicle’s starting system.

Troubleshooting Common Issues with Starter Motors.

When faced with issues related to starter motors, it is crucial to understand the symptoms and possible causes to troubleshoot effectively. One common problem that often occurs is grinding noises when attempting to start the engine.

This could be a sign of worn-out gears in the starter motor, indicating the need for replacement or repair. Additionally, slow cranking, where the engine takes longer than usual to turn over, may suggest battery-related issues or problems with the starter motor itself.

To diagnose these problems accurately, start by checking the battery voltage using a multimeter to ensure it is delivering adequate power to the starter motor. If the voltage is within the normal range but slow cranking persists, it might be necessary to examine the connections between the battery and starter motor for corrosion or loose wiring.

In cases of failure to engage, where there is no response when turning the key, inspecting the solenoid in the starter system could reveal potential malfunctions that impede proper engagement.

Once diagnosed, potential solutions can vary depending on the specific issue identified. For instance, if grinding noises persist, lubricating or replacing damaged gears could resolve this problem effectively.

In contrast, addressing slow cranking may involve cleaning corroded terminals or replacing a weak battery to ensure an adequate power supply to crank the engine swiftly. In scenarios of failure to engage, adjusting or replacing faulty solenoids can often restore proper functionality and enable seamless initiation of the engine.

By carefully monitoring symptoms and following systematic troubleshooting steps like those outlined above, individuals can address common issues associated with faulty starter motors promptly and effectively.

Being proactive in identifying and resolving these problems not only ensures smooth vehicle operation but also contributes to prolonging the lifespan of crucial components within a car’s engine system.

Future Innovations in Starter Motor Technology.

As technology advances in the automotive industry, starter motor technology is also evolving to enhance efficiency and reliability. One of the promising developments on the horizon is the integration of sensors into starter motors, giving rise to smart starters.

These intelligent starters can monitor various parameters like engine temperature, battery condition, and even driving habits to optimize the starting process. By utilizing data from these sensors, smart starters can adjust their performance for improved efficiency and longevity.

Looking ahead, starter motors are likely to play a significant role in hybrid systems and electric vehicles due to their critical function in initiating the engine or motor. Integration with hybrid systems could involve starter motors that seamlessly transition between traditional engine starting and engaging with electric propulsion systems, contributing to a more integrated and efficient vehicle operation.

Similarly, in all-electric vehicles, starter motors might function not only as starters but also as generators for energy regeneration during braking or coasting, adding value beyond their conventional role.

These advancements signal a shift towards more sophisticated starter motor technologies that align with the broader trends of electrification and automation in the automotive sector. As vehicles become increasingly complex and interconnected, starter motors are poised to evolve into smart components that actively contribute to overall vehicle performance and energy management.

By embracing these innovations, manufacturers can deliver cars with smoother operations, better fuel efficiency, and reduced environmental impact while ensuring drivers experience seamless starting capabilities across different driving conditions.

Conclusion.

In conclusion, the car engine starter motor stands as a fundamental component that plays a crucial role in initiating the operation of internal combustion engines. Its efficient functioning is paramount to ensure the smooth start-up and reliable performance of vehicles.

As we have delved into the essentials of starter motors, it becomes evident that understanding the intricacies of these mechanisms is essential for automotive enthusiasts, mechanics, and engineering students alike.

Key takeaways from this exploration include the significance of regular maintenance practices to uphold optimal performance and longevity of starter motors. By grasping the key components, types utilized in cars, factors affecting performance, and common troubleshooting techniques, individuals can enhance their ability to diagnose issues promptly and execute solutions effectively.

This knowledge empowers individuals to safeguard against potential malfunctions that may impede vehicle operation. Therefore, a well-informed approach to comprehending, maintaining, and troubleshooting starter motors serves as a cornerstone for ensuring the efficient functionality of these critical devices within automobile systems.