Unveiling the Mystery of Car Engine Alternator

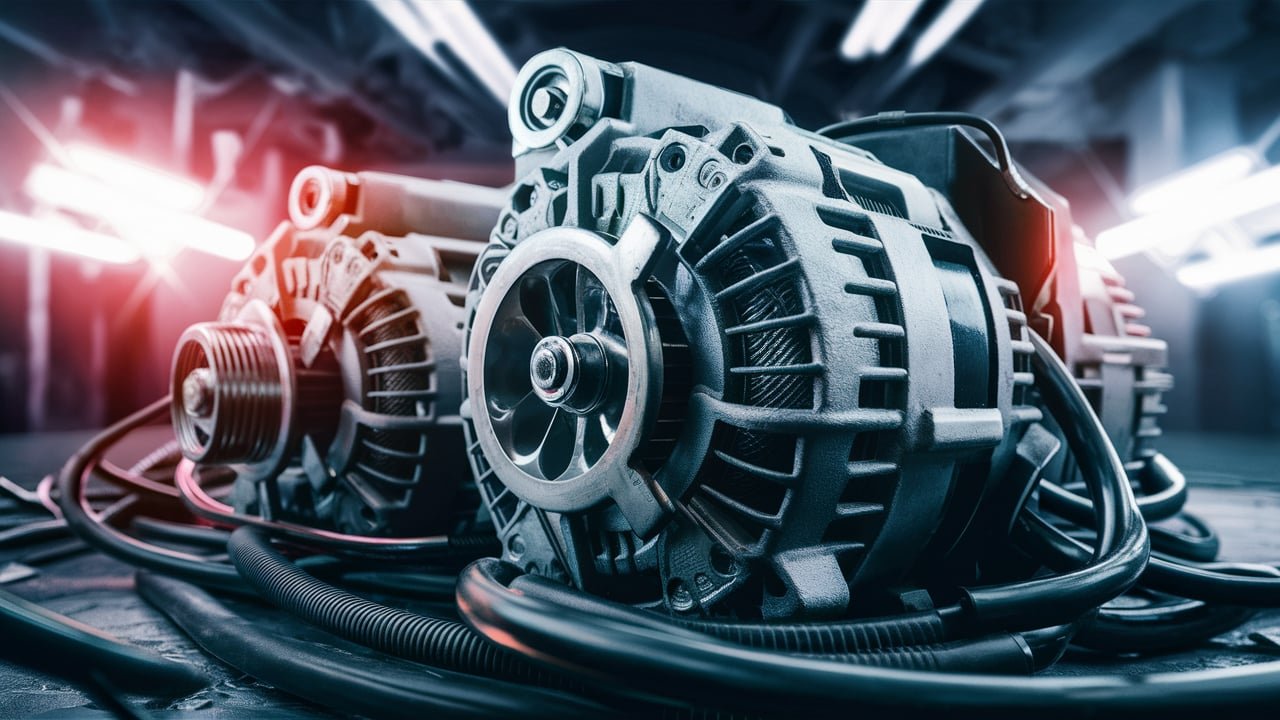

Nestled within the intricate web of a car’s internal components lies a vital yet often overlooked player – the car engine alternator. Defined as an electromechanical device, the alternator boasts a crucial role in vehicle functionality by harnessing mechanical energy from the engine to generate electrical power.

Appealing to auto enthusiasts, mechanics, car owners, and engineering students alike, understanding the enigmatic workings of alternators transcends mere curiosity; it equips individuals with fundamental knowledge essential for maintaining, diagnosing, and optimizing vehicular performance.

In unraveling the veil shrouding car engine alternators, enthusiasts delve into a realm where precision meets invention – where coils spin within magnetic fields to conjure electricity essential for charging batteries and powering electrical systems.

For mechanics navigating under hoods or engineering students peering into the heart of automotive innovation, grasping the intricacies of alternators unveils not just technical marvels but also empowers informed decision-making regarding maintenance and enhancements.

Through this exploration of an unsung hero in vehicle propulsion, a world teeming with possibilities unfolds – beckoning readers to embark on a journey towards enlightenment intertwined with automotive prowess and technical acumen.

Understanding Car Engine Alternators.

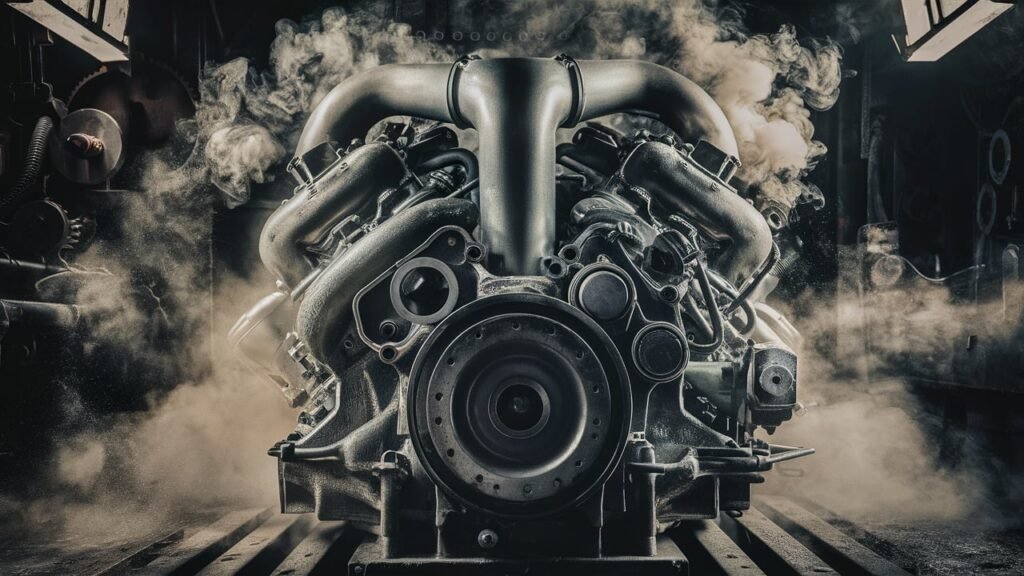

To grasp the intricacies of car engine alternators, it’s essential to delve into the components that work harmoniously within this vital automotive system. At the core of an alternator lies the rotor and stator.

The rotor, typically a set of windings wound around an electromagnet, rotates within the stator – a stationary assembly also composed of wire windings. When the engine is in motion, the rotation of the rotor induces an alternating current (AC) in the stator through electromagnetic induction.

Among these components are diodes crucial for converting AC to direct current (DC). Diodes act as one-way electrical valves ensuring that only DC flows through the circuitry. This rectification process allows for consistent charging of the vehicle’s battery by converting mechanical energy from the engine into electrical power.

Furthermore, a vital player in this symphony is the voltage regulator. Acting as a brain for the alternator, it monitors and maintains output voltage levels to prevent overcharging or undercharging of the battery while regulating power distribution to different electrical components.

Lastly, we encounter the pulley system – often overlooked but crucial for transferring mechanical energy effectively from the engine to drive the alternator. The pulley system connects to various belt-driven accessories in modern vehicles like water pumps and air conditioning compressors.

A well-functioning pulley system ensures optimal rotational speed for the alternator to generate sufficient electricity at varying engine speeds. Together, these components form a sophisticated mechanism dedicated to transforming mechanical energy produced by your vehicle’s engine into electrical power essential for keeping your car running smoothly and powering its electrical systems efficiently.

How Car Alternators Generate Electricity through Electromagnetic Induction.

Car alternators serve as the powerhouse behind your vehicle’s electrical system, converting mechanical energy into electrical power. Understanding how alternators work sheds light on their essential role in maintaining a fully operational vehicle. The process begins with a crucial concept: electromagnetic induction.

As the engine runs, it spins the alternator’s rotor inside the stator—a set of wire coils. This rotation generates a changing magnetic field which induces an electric current in the stator windings according to Faraday’s Law of Electromagnetic Induction.

The relationship between engine speed measured in RPM (revolutions per minute) and alternator output voltage is pivotal for ensuring proper charge levels within the automotive electrical system. At lower RPMs, the alternator may not produce sufficient electricity to power all components effectively, potentially causing dimming lights or weak battery charging.

Conversely, excessive RPMs might overcharge the battery or damage electronic components due to excess voltage output. Engineers meticulously design alternator systems with built-in safeguards like voltage regulators to maintain stable electrical output across various engine speeds, striking a delicate balance between efficiency and functionality.

Illustrating this process through practical examples can enhance comprehension for auto enthusiasts and engineering students alike. Visualizing how altering engine speed affects the alternator output—similar to adjusting a radio tuner for optimal reception—can demystify this technical aspect of vehicle operation.

By articulating these mechanisms clearly, individuals gain a deeper appreciation for the intricacies of car alternators and their contributions to powering modern automobiles efficiently and reliably.

Common Alternator Issues.

Car engine alternators, although durable and reliable, can face various issues over time due to wear and tear or electrical malfunctions. Recognizing these common problems is crucial for maintaining a vehicle’s electrical system. One prevalent sign of alternator trouble is dimming lights while driving.

If headlights or interior lights flicker or lose brightness intermittently, it could indicate an insufficient charge reaching the battery. This often occurs when the alternator fails to generate adequate power output.

Another noticeable symptom of potential alternator issues is strange noises emanating from the engine bay while the vehicle is running. A grinding, whining, or screeching sound may suggest a failing bearing inside the alternator assembly.

If left unaddressed, this could lead to complete alternator failure and subsequent electrical system shutdown. Moreover, frequent battery failures despite replacements could point towards an underlying alternator problem causing inadequate recharging of the battery.

To troubleshoot potential alternator issues effectively, car owners and mechanics should perform voltage output tests using a multimeter. By connecting the multimeter to the battery terminals while the engine is running, one can observe if the voltage output falls within the recommended range (generally around 13.5 to 14.5 volts).

Deviations from this range might indicate a malfunctioning alternator that requires inspection or replacement by a professional technician. Additionally, checking the belt tension connected to the alternator pulley system is vital in ensuring proper rotation for generating electricity efficiently.

By understanding these common signs of alternator problems and following systematic troubleshooting steps, individuals can address issues promptly to prevent further damage to their vehicles’ electrical systems.

Early detection and resolution of alternator malfunctions not only enhance vehicle safety but also contribute to prolonging the lifespan of critical components like batteries and electrical circuits within modern cars.

Maintenance Tips for Car Alternators.

Regular maintenance of your car’s alternator is crucial to ensure its longevity and optimal performance. Here are some effective tips to keep your alternator in top condition:

1. **Inspect the Belt:** Routinely check the alternator belt for signs of wear, cracks, or fraying. A worn-out belt can slip or break, affecting the alternator’s ability to charge the battery properly. Replace the belt if you notice any issues to prevent potential breakdowns.

2. **Clean Terminals:** Over time, corrosion or dirt can accumulate on the alternator terminals, hindering electrical conductivity. Use a terminal cleaner or a simple solution of baking soda and water to remove any buildup gently. Maintaining clean terminals ensures a stable connection and efficient power transmission.

3. **Test Charging Performance:** To verify that your alternator is functioning correctly, use a multimeter to measure charging output. With the engine running, check the voltage at the battery terminals; it should read around 13.5 to 14.5 volts. Consistent testing helps detect early signs of alternator malfunctions before they escalate.

In addition to these tasks, consider implementing preventive measures:

– **Avoid Overloading Electrical Systems:** Be mindful of adding excessive electrical accessories to your vehicle that could strain the alternator. Too much load on the system can lead to premature wear and reduced efficiency.

– **Ensure Proper Ventilation:** Adequate airflow around the alternator is essential for temperature regulation. Insufficient ventilation can cause overheating and diminish the alternator’s performance over time.

By incorporating these maintenance practices into your routine inspections, you can prolong your alternator’s lifespan and minimize unexpected failures while ensuring a reliable power supply for your vehicle’s electrical components.

Upgrading a car’s alternator.

Upgrading a car’s alternator for improved performance can be a game-changer for enthusiasts seeking to power additional electrical components in modified vehicles. When considering upgrading from stock alternators to higher output models, it is essential to evaluate various factors carefully.

One primary consideration is the amperage rating of the alternator. Higher output alternators can provide more electrical capacity, accommodating added features like high-powered stereo systems or aftermarket lighting without strain.

Moreover, ensuring compatibility with the vehicle’s electronics is crucial when selecting an aftermarket alternator. Different vehicles may have unique requirements based on their electrical systems.

For instance, modern cars equipped with advanced computer systems demand precise voltage regulation to prevent disruptions or damage. Opting for an alternator that integrates seamlessly with these electronics is paramount to avoid any compatibility issues that could compromise the vehicle’s functionality.

Installation requirements should also be taken into account when upgrading alternators for performance. Some aftermarket alternators may necessitate modifications or additional components for proper fitment and operation.

Understanding these installation needs beforehand can prevent complications during the upgrade process and ensure a successful integration. By carefully assessing amperage ratings, compatibility with vehicle electronics, and installation demands, auto enthusiasts can make informed decisions when enhancing their car’s electrical system through alternator upgrades.

Future Trends in Alternator Technology.

Advancements in alternator technology are continuously shaping the automotive industry, with a focus on enhancing efficiency and performance. One notable trend is the integration of smart charging systems into alternators.

These systems utilize sensors to monitor driving conditions, battery health, and power demands, allowing the alternator to adjust its output accordingly for optimal efficiency. By dynamically adapting the charging process, smart alternators help extend battery life and reduce fuel consumption by optimizing electrical power generation.

Looking ahead, potential developments in alternator technology may involve incorporating regenerative braking systems into the charging process. Regenerative braking harnesses energy typically lost during braking and converts it into electricity to charge the battery.

By combining this innovative technology with alternators, vehicles can further improve energy efficiency and reduce overall environmental impact. Imagine a scenario where every time you brake, your car not only slows down but also replenishes its energy reserves—a promising step towards sustainable transportation solutions.

Furthermore, future alternator designs might explore the use of lightweight materials to enhance performance without sacrificing durability. Lightweight alternators could contribute to improved vehicle fuel efficiency by reducing overall weight and increasing power-to-weight ratios.

Integrating advanced materials like carbon fiber or aluminum alloys into alternator construction could revolutionize how electrical power is generated within vehicles, paving the way for more efficient and eco-friendly transportation options.

As automotive engineering continues to evolve, these cutting-edge developments in alternator technology align with broader trends towards sustainability and innovation in the automotive sector.

Conclusion: Unraveling the Enigma of Car Engine Alternators.

In concluding our exploration of car engine alternators, it becomes evident that these complex yet vital components play a crucial role in powering modern vehicles.

By converting mechanical energy into electrical power through a combination of rotor-stator interactions and diode-controlled systems, alternators ensure continuous battery charging and enable seamless operation of various electrical components while the engine is running.

Understanding the intricacies of alternators is not only beneficial for auto enthusiasts, mechanics, car owners, and engineering students but also empowers individuals to take proactive measures in maintaining their vehicles’ performance.

It is paramount for readers to further engage with the knowledge shared in this article to make informed decisions regarding the upkeep and potential upgrades of their vehicle’s alternator system. By adhering to routine maintenance practices like belt inspections, terminal cleaning, and regular voltage testing, individuals can prolong the lifespan of alternators and prevent unexpected breakdowns.

Delving deeper into the realm of alternator technology equips individuals with the expertise needed to navigate common issues efficiently and explore advanced upgrades that cater to specific vehicle requirements. Embracing this understanding showcases a commitment to vehicle care and ensures optimal performance on every journey undertaken.