Things You Didn’t Know About Car Engine Piston

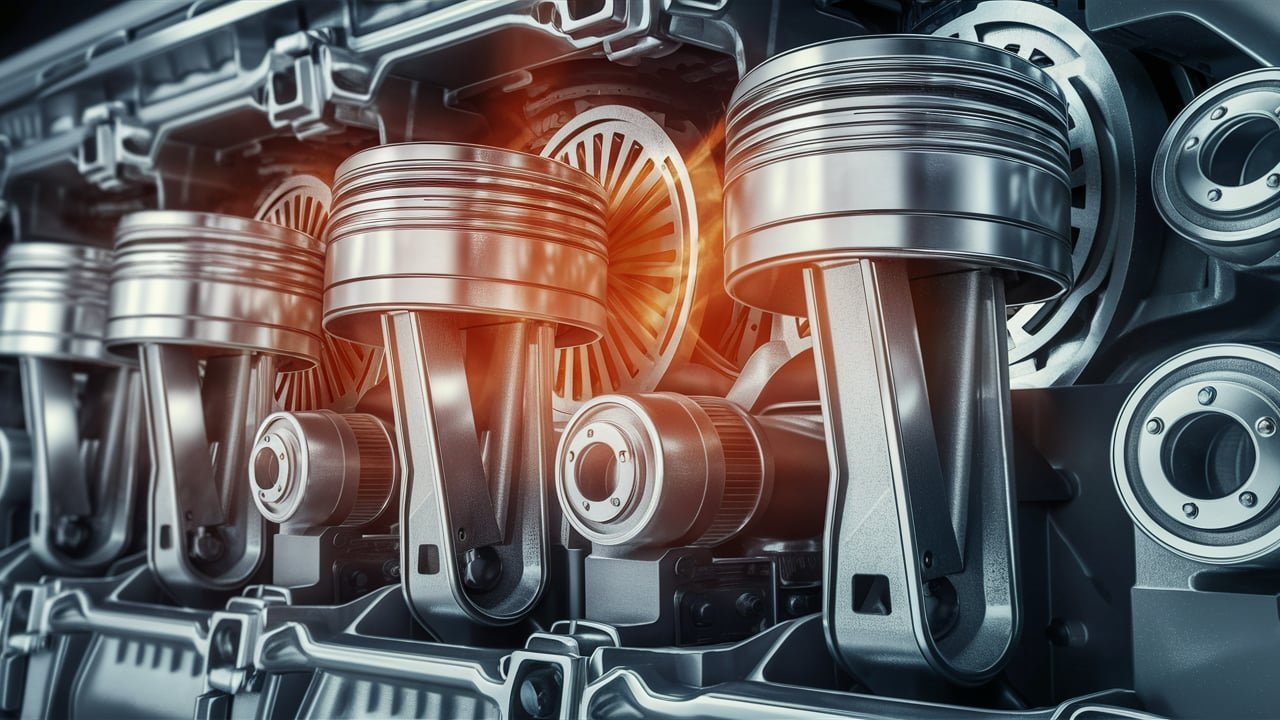

A car engine piston is a critical component of a car’s internal combustion engine. It is a metal piece located inside each cylinder of the engine and moves up and down to facilitate the combustion process. Here’s a detailed overview of what a piston does and how it works:

Function.

Intake Stroke: The piston moves down, creating a vacuum in the cylinder, which draws in air and fuel through the intake valve.

. Compression Stroke: The piston moves up, compressing the air-fuel mixture rapidly, which heats it up and makes it more volatile. Power Stroke: The spark plug ignites the mixture, causing an explosion that forces the piston down, converting the heat energy into mechanical energy. This energy is transferred to the crankshaft through the connecting rod, ultimately powering the car’s wheels. Exhaust Stroke: The piston moves up again, pushing the exhaust gases out of the cylinder through the exhaust valve.

Importance.

- Energy Conversion: The piston plays a crucial role in converting the heat energy from combustion into mechanical energy, which powers the car.

- Air-Tight Seal: Piston rings ensure a tight seal between the piston and the cylinder, ensuring efficient combustion and preventing oil from leaking into the combustion chamber.

Common Problems.

- Piston Slap: Worn-out pistons can cause a noisy “slap” sound due to increased gaps between the piston and cylinder

. Worn Piston Rings: Worn piston rings can lead to reduced engine performance and increased oil consumption. Burnt Pistons: Incorrect setup or dirty fuel injectors can cause the pistons to become burnt, reducing engine power. Cracked Pistons: Poor quality gasoline can cause pistons to crack, impacting engine performance.

Maintenance.

- Regular Service: Regular maintenance is crucial to identify and address any issues with the pistons before they become severe.

- High Octane Fuel: Using high octane fuel can help prevent piston damage caused by low octane fuel

. Quality Oil: Using high-quality oil and changing it regularly can help maintain the health of the pistons and other engine components.

In summary, a car engine piston is a vital component that plays a central role in the combustion process, converting heat energy into mechanical energy to power the car. Proper maintenance and use of high-quality components are essential to ensure the longevity and performance of the pistons.

In the intricate symphony of a car’s engine, the humble piston plays a crucial role that often goes unnoticed by many. A car engine piston is a cylindrical component that reciprocates within a cylinder bore, converting energy from expanding gas into mechanical motion.

Despite its unassuming appearance, the importance of pistons in the functioning of an engine cannot be overstated. These unassuming metal rods act as the powerhouse of internal combustion engines, driving vehicles forward with precision and power.

As we delve deeper into the heart of automotive engineering, uncovering seven fascinating aspects about car engine pistons promises to unveil a world of innovation and ingenuity. From the intricacies of their anatomy comprising crowns, skirts, and pin bores to the impactful materials used in their manufacturing like aluminum and steel—the journey will redefine your understanding of these fundamental engine components.

Join us on an enlightening expedition where we explore how unsung heroes like piston rings ensure optimal performance while decoding the complexities behind piston size and compression ratios for enhanced engine efficiency. Prepare to be captivated as we unravel common piston problems, present high-performance solutions for enthusiasts seekin.

The anatomy of a piston.

The anatomy of a piston is crucial to its function within an engine. Understanding the various components – the crown, skirt, and pin bore – provides insight into how these parts work together to power your vehicle. The crown of a piston is the top surface responsible for withstanding intense heat and pressure during combustion.

It needs to be durable yet lightweight to promote efficiency. Imagine the crown as the heart of the piston, enduring extreme conditions without faltering, much like a champion athlete in the midst of a demanding race.

Moving down to the skirt, this section resembles the lower body of the piston that helps maintain stability within the cylinder bore. The design and dimensions of the skirt impact factors such as friction and engine noise.

Picture the skirt as an adept dancer gliding smoothly across a stage; its movements are essential for maintaining balance and harmony within the engine structure. Lastly, we delve into the pin bore – a vital part where the wrist pin attaches to connect the piston with the connecting rod.

This connection point influences how efficiently force is transmitted through your engine. Think of it as a precision mechanical joint that ensures seamless coordination between components.

Each segment – crown, skirt, and pin bore – plays an indispensable role in enhancing overall performance and reliability. The synergy among these components highlights engineering precision at its finest, showcasing how even minor adjustments can significantly impact an engine’s efficiency and longevity.

Appreciating these intricate details not only deepens our understanding of car engines but also underscores the meticulous craftsmanship required to propel vehicles forward seamlessly and reliably on roads worldwide.

Materials Used in Piston Manufacturing.

When it comes to the construction of car engine pistons, the choice of material plays a crucial role in determining the performance and durability of these essential components. The three primary materials utilized in piston manufacturing are aluminum, steel, and forged aluminum.

Aluminum pistons are popular due to their lightweight nature, which reduces the overall mass that needs to be reciprocated within the engine, enhancing fuel efficiency and allowing for higher RPM capabilities.

Steel pistons, although heavier, offer greater strength and heat resistance compared to aluminum variants, making them suitable for high-performance engines where increased temperatures and pressures are common. Forged aluminum pistons combine the best of both worlds by utilizing a forging process that enhances strength while retaining the benefits of aluminum’s lighter weight.

The material choice impacts not only performance but also durability. For instance, steel pistons are less prone to expansion under high temperatures compared to aluminum counterparts, reducing the risk of piston slap—a condition where slack between cylinder walls and piston causes knocking noises during engine operation.

Understanding how each material behaves under various conditions is vital for optimizing an engine’s reliability and efficiency over its lifespan.

Piston Rings: Unsung Heroes.

Piston rings, often overshadowed by the piston itself, play a critical role in the proper functioning of an engine. Positioned around the outer circumference of the piston, these small but mighty components are responsible for sealing the combustion chamber. Their precise fit and ability to maintain optimal pressure within the cylinder are crucial for efficient engine operation.

When piston rings wear out or fail to seal correctly, it can have detrimental effects on engine performance. Leaking compression due to worn-out rings leads to decreased power output and efficiency. Furthermore, inadequate sealing can result in oil consumption issues, as oil from the crankcase may enter the combustion chamber, leading to increased emissions and potential damage to catalytic converters.

To ensure that piston rings continue to perform effectively, regular maintenance is key. Checking for signs of excessive oil consumption or reduced engine power can indicate potential ring wear. Proper lubrication and avoiding prolonged high-speed driving without allowing the engine to warm up fully are practices that can extend the lifespan of piston rings and maintain optimal engine efficiency.

In essence, while pistons may get much of the attention when discussing engine components, it’s important not to overlook the indispensable role played by piston rings in maintaining a well-sealed combustion chamber. These unsung heroes quietly work behind the scenes to ensure your engine runs smoothly and efficiently.

Understanding Piston Size and Compression Ratio.

When delving into the intricate world of car engine pistons, understanding the relationship between piston size and compression ratio is vital. The compression ratio in an engine represents the difference in volume inside the cylinder when the piston is at the bottom of its stroke (bottom dead center) compared to when it’s at the top of its stroke (top dead center).

This ratio plays a crucial role in determining engine performance, efficiency, and fuel consumption. Higher compression ratios generally lead to more power output but can also require higher-octane fuels to prevent knocking.

The size of the piston directly influences this compression ratio. For example, larger pistons with larger diameters will naturally displace more volume within the cylinder when they move, affecting the compression ratio accordingly.

On the other hand, shorter pistons can alter the dynamic characteristics within the combustion chamber, impacting factors like air turbulence and fuel atomization. Engineers carefully calculate these dimensions to optimize performance while considering factors like engine displacement and intended usage scenarios.

In practical terms, modifications to piston size can be seen in high-performance engines aiming for more power output by increasing compression ratios through using larger pistons or those with different crown designs.

Conversely, some eco-friendly vehicles may utilize smaller pistons to achieve better fuel efficiency by adjusting compression ratios for optimal combustion efficiency without sacrificing power. Understanding these dynamics not only sheds light on how engines operate but also underscores the meticulous engineering that goes into maximizing their potential through piston design considerations.

Problems with Pistons: Common Issues & Solutions.

Car engine pistons, despite being robust components, can encounter various issues that impact overall engine performance. One common problem is piston slap, characterized by a knocking sound when the piston changes direction at the top or bottom of the cylinder.

This occurs due to excessive piston-to-cylinder clearance caused by wear over time. To prevent piston slap, using high-quality synthetic motor oils can help maintain proper lubrication and reduce friction between moving parts.

Another issue faced by pistons is scuffing, which happens when there is insufficient lubrication between the piston skirt and cylinder wall, leading to metal-on-metal contact. Proper maintenance practices such as regular oil changes and ensuring the engine operates within recommended temperature ranges can mitigate scuffing. Additionally, using fuel additives that contain friction modifiers can assist in reducing wear on piston surfaces.

Overheating is a critical problem that can affect pistons, often resulting from poor cooling system efficiency or running the engine under extreme conditions for extended periods. Installing an efficient cooling system and monitoring coolant levels regularly can help prevent overheating of pistons.

Moreover, maintaining proper air-fuel ratios and avoiding aggressive driving habits can contribute to reducing heat buildup in the engine, preserving the integrity of the pistons.

To ensure optimal performance and longevity of car engine pistons, drivers must adhere to routine maintenance schedules provided by manufacturers. By addressing these common issues proactively and implementing preventative measures through proper lubrication, cooling system upkeep, and careful driving practices, enthusiasts can enjoy a smoother-running engine with prolonged piston life expectancy.

High-performance pistons.

High-performance pistons cater to car enthusiasts seeking to elevate their engine’s capabilities. Aftermarket pistons are crafted with precision and innovative designs, often using advanced materials like aluminum alloys, titanium, or steel.

Lightweight pistons are a favored choice among performance seekers due to their ability to reduce reciprocating mass within the engine, enhancing responsiveness and revving potential. These specialized pistons boast intricate designs that optimize airflow and combustion efficiency, resulting in increased power output without compromising reliability.

Moreover, coatings play a pivotal role in improving piston performance. High-tech coatings like ceramic thermal barriers can enhance heat dissipation and reduce friction between the piston and cylinder walls.

These coatings not only contribute to better overall engine efficiency but also aid in minimizing wear and tear on critical components. Enthusiasts often turn towards piston designs featuring strengthened skirts or unique shaping for enhanced structural integrity under high-stress conditions, typical of high-performance driving scenarios.

In the realm of high-performance pistons, customization options abound for individuals striving for specific enhancements tailored to their driving preferences. For example, domed pistons are ideal for increasing compression ratios in engines designed for optimal power output at higher RPMs.

Additionally, dished pistons find their niche in turbocharged applications by promoting controlled detonation and efficient fuel combustion. By exploring these specialized piston variations, enthusiasts can unleash the full potential of their engines while fine-tuning performance characteristics according to their desired outcomes.

Ultimately, high-performance pistons stand as essential components in transforming ordinary vehicles into powerhouse machines capable of delivering thrilling driving experiences on both road and track alike.

Eco-Friendly Innovations: Pistons Going Green.

With the ever-growing focus on sustainability and environmental impact, the automotive industry is not exempt from the shift towards eco-conscious practices. One notable area where this change is being observed is in the materials used for car engine pistons.

Traditionally, pistons have been predominantly made from aluminum due to its lightweight nature and heat dissipation properties. However, a significant stride towards sustainability has been made with the introduction of recycled aluminum as a preferred material for piston manufacturing.

Recycled aluminum offers several environmental benefits compared to virgin aluminum production. The process of recycling aluminum consumes significantly less energy than producing new aluminum from raw ore, leading to reduced carbon emissions and energy consumption.

By incorporating recycled aluminum into piston production, manufacturers are not only reducing their ecological footprint but also contributing to a circular economy by repurposing materials that might otherwise end up in landfills.

Moreover, beyond the environmental advantages of using recycled aluminum for pistons, there are performance benefits as well. Recycled aluminum can be engineered to meet specific strength and durability requirements while maintaining its lightweight characteristics.

This means that engines equipped with pistons made from recycled aluminum can still benefit from improved fuel efficiency and power delivery without compromising on performance or reliability. As such, these eco-friendly innovations in piston materials herald a more sustainable future for automotive engineering while meeting the demands of both efficiency and environmental responsibility.

The Future of Engine Piston Technology.

As technology continues to evolve, so does the field of engine piston design. Today, researchers are delving into innovative concepts to enhance engine performance and efficiency through advanced piston technologies. One of the promising trends in piston development is the exploration of smart pistons.

These intelligent components can adjust their behavior based on real-time data from sensors within the engine, optimizing combustion processes and overall efficiency. By adapting to changing conditions dynamically, smart pistons aim to maximize power output while minimizing emissions and fuel consumption.

In addition to smart pistons, another groundbreaking avenue being explored is the use of 3D-printed pistons. This cutting-edge manufacturing technique allows for intricate designs that were previously impossible with traditional casting methods.

3D-printed pistons offer precise control over geometry and internal structures, enabling engineers to fine-tune performance characteristics like heat dissipation and weight distribution. This customization potential opens doors to creating pistons tailored for specific engines or applications, optimizing efficiency and durability like never before.

The potential benefits of these future piston technologies.

The potential benefits of these future piston technologies are enormous. Smart pistons could revolutionize how engines operate by constantly adjusting parameters for optimal performance under varying conditions, leading not only to increased power but also reduced carbon footprint.

On the other hand, 3D-printed pistons offer a level of intricacy in design that can significantly enhance engine efficiency and reliability. As these advanced technologies continue to develop and mature, we may witness a new era in engine piston design that pushes boundaries and sets new standards for automotive excellence.

How do piston rings ensure an air-tight seal?

Piston rings ensure an air-tight seal by maintaining a thin film of oil between the rings and the cylinder liner. This oil film fills the space between the rings and the liner, allowing the rings to maintain a tight seal despite traveling linearly up and down within the cylinder. The rings are attached to the piston within recessed groves and are designed to withstand significant pressure and temperature variations.

The compression rings, located closest to the combustion space, form the seal between the crankcase and combustion space, while the scraper rings regulate the amount of oil used for lubrication between the piston rings and cylinder liner.

What are the common problems with engine pistons?

Common problems with engine pistons include:

- Piston ring flutter: This occurs when the rings oscillate vertically within the piston grooves, compromising the seal between the ring and the cylinder wall, leading to a loss of cylinder pressure and power

. Valve float: This occurs when the valve springs cannot act quickly enough to close the valves at high engine speeds, resulting in piston-to-valve contact and potentially severe engine damage. Lubrication breakdown: At high speeds, the lubrication of the piston cylinder wall interface can break down, limiting piston speed and potentially causing engine damage.

How does the four-stroke cycle work in detail?

The four-stroke cycle involves four separate strokes of the piston:

- Intake Stroke: The piston moves down, drawing an air-fuel mixture into the cylinder through the open intake valve. The intake valve must be open while the piston is at the bottom dead center (B.D.C.) to create a partial vacuum in the cylinder

. Compression Stroke: The intake valve closes, and the piston moves up, compressing the air-fuel mixture in preparation for ignition. Both intake and exhaust valves are closed during this stage.

Power Stroke: The compressed air-fuel mixture is ignited by a spark plug (in a gasoline engine) or heat generated by high compression (in a diesel engine), forcing the piston back down the cylinder and producing mechanical work to turn the crankshaft.

Exhaust Stroke:

The piston moves up again, and the exhaust valve opens, allowing the spent air-fuel mixture to exit the cylinder through the exhaust port.These four strokes occur sequentially in each cylinder, with all cylinders completing a stroke simultaneously, allowing the pistons to work together like steps on an engine.

Conclusion – Unveiling the Power Within.

Car engine pistons may appear like small components within the intricate machinery of an automobile, yet their significance in the performance and power output of an engine is immense.

From understanding the anatomy of a piston to delving into materials used in manufacturing, it becomes evident that these seemingly simple devices are the unsung heroes propelling our vehicles forward. The exploration of common issues, innovative high-performance options, and eco-friendly advancements only scratches the surface of what pistons entail.

As we unravel the complexities of car engine pistons, we realize that these cylindrical marvels are not merely mechanical parts but precision-engineered instruments responsible for harmonizing combustion forces within engines.

From preventing leaks in combustion chambers to optimizing compression ratios for peak efficiency, each piston plays a vital role. By acknowledging and appreciating the intricacies of pistons, we truly unveil the power they hold within—driving us towards a future where automotive technology continues to push boundaries and redefine possibilities.