Unraveling the Mystery: The Car Engine Oil Cooler

An engine oil cooler is a heat-exchanging device that helps maintain the temperature of the engine oil. Its main purpose is to remove excess heat from the engine oil, which can help improve engine performance and longevity. The oil cooler works by circulating the hot engine oil through a small radiator-like unit, where it exchanges heat with the surrounding air or coolant.

This helps lower the oil temperature, typically by 30 degrees or more. Engine oil coolers are particularly beneficial for high-performance, high-revving engines that generate a lot of heat. They help keep the oil viscosity at the optimal level and prevent premature oil breakdown. Some key benefits of an engine oil cooler include:

- Improved engine cooling and performance

- Maintained oil viscosity for better lubrication

- Reduced risk of oil breakdown and engine wear

- Easier oil circulation and flow

However, there are also some potential downsides, such as the risk of coolant leaks and the need for additional oil volume. Whether an oil cooler is worth installing depends on factors like driving conditions, engine type, and climate. In summary, an engine oil cooler is a valuable accessory that can help extend the life and performance of an engine by keeping the oil temperature in an optimal range.

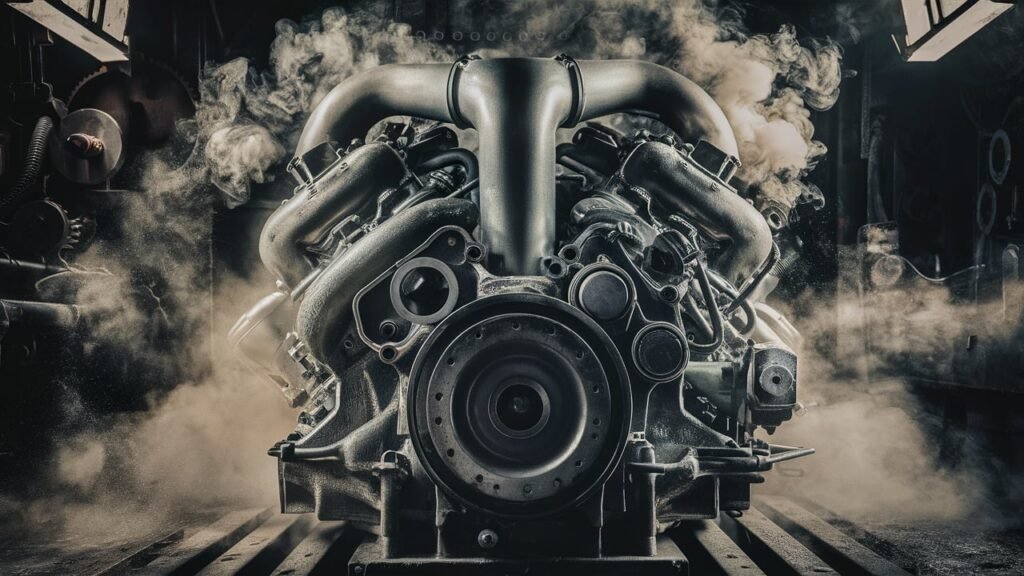

Delving into the intricate mechanics of automotive engineering unveils a critical component hidden within the labyrinthine structure of a car’s engine – the enigmatic car engine oil cooler. Beyond its discreet presence, this apparatus plays a pivotal role in orchestrating the symphony of heat management within your vehicle’s heart.

As we embark on unraveling this esoteric mechanism, we invite auto enthusiasts, seasoned mechanics, and astute engineering students to delve deeper into the core principles governing optimal temperature regulation in automobiles.

Amidst the hum of pistons and the rhythmic purr of combustion cycles lies a symbiotic relationship between a car engine and its oil cooler – a bond forged through precision and necessity.

For those craving technical enlightenment or eager minds thirsting for knowledge, understanding how these cooling mechanisms intricately interlace with an engine’s functionality unveils a realm where efficiency reigns supreme.

Let us navigate this realm together, shedding light on the unsung hero safeguarding engines against the perils of overheating while beckoning aficionados and curious minds alike to explore further depths in this world of vehicular intricacy.

Overview of Car Engine Oil Coolers.

Car engine oil coolers play a crucial role in regulating the temperature of engine oil to ensure optimal performance. By managing the heat generated during the combustion process, these coolers help maintain the viscosity of the oil, allowing it to lubricate engine components effectively.

Without proper cooling, high operating temperatures can cause oil breakdown and lead to accelerated wear and potential damage to vital engine parts. Think of an oil cooler as a silent guardian working behind the scenes to keep your engine running smoothly.

To prevent overheating, oil coolers are strategically placed in the vehicle’s cooling system, typically near the radiator or in a location that allows for efficient heat dissipation. These coolers come in various shapes and sizes, catering to different vehicle models and engine configurations.

Common materials used in the construction of effective oil coolers include aluminum and copper due to their excellent thermal conductivity properties. These materials facilitate heat transfer from the hot oil to the surrounding air or coolant, ensuring efficient cooling without compromising structural integrity.

Maintaining proper engine temperature is essential for maximizing engine longevity and preventing premature wear. By incorporating an oil cooler into your vehicle’s setup, you invest in safeguarding its long-term health.

The ability of these devices to extend engine life by reducing thermal stress cannot be overstated. With advancements in material science and design techniques, modern car engine oil coolers have evolved to become more durable, efficient, and integral components of automotive cooling systems.

Types of Car Engine Oil Coolers.

Car engine oil coolers come in two primary types: air-cooled and liquid-cooled. Air-cooled oil coolers rely on the circulation of air to dissipate heat from the oil. These coolers are typically mounted in areas where they can be exposed to airflow, such as behind the grille or under the vehicle. By utilizing the natural movement of air, these coolers efficiently regulate oil temperature without requiring additional fluids for cooling.

On the other hand, liquid-cooled oil coolers utilize coolant or water to enhance their cooling capabilities. These systems circulate a dedicated coolant through a separate cooling circuit that absorbs heat from the oil before being cooled in a radiator-like setup. Liquid-cooled oil coolers offer more precise temperature control and are often preferred in high-performance vehicles where maintaining optimal operating temperatures is critical for engine efficiency.

When comparing air-cooled and liquid-cooled oil coolers, several factors come into play. Air-cooled variants are generally simpler in design and installation, making them more cost-effective and easier to maintain compared to liquid-cooled counterparts.

However, liquid-cooled oil coolers provide superior heat dissipation properties, ensuring more consistent oil temperatures under varying driving conditions. While air-cooled systems may suffice for everyday use, liquid cooling is often favored in performance applications where thermal management is paramount.

In conclusion, the choice between air-cooled and liquid-cooled car engine oil coolers depends on factors like intended use, budget constraints, and performance requirements. Understanding the distinct advantages and disadvantages of each type allows automotive enthusiasts, mechanics, and engineering students to make informed decisions when selecting an appropriate oil cooling solution for their vehicles.

Installation and Maintenance Procedures.

Installing a car engine oil cooler system correctly is crucial for its efficient operation. The first step involves selecting the appropriate oil cooler size and type based on the vehicle’s engine specifications and cooling requirements.

Begin by mounting the oil cooler in a location that ensures adequate airflow for optimal heat dissipation, away from sources of extreme heat or debris. Securely attach the oil lines, ensuring proper fittings are used to prevent leaks. Carrying out this installation process meticulously is essential to avoid potential issues down the road.

To maintain the longevity and performance of the oil cooler, regular maintenance is key. Periodically inspect the oil lines for any signs of wear or leaks, tightening connections as needed. It’s essential to monitor the coolant levels if using a liquid-cooled oil cooler and ensure its quality remains within manufacturer recommendations.

Additionally, cleaning both the exterior fins and interior passages of the oil cooler from debris or contaminants will help uphold its efficiency over time. By adhering to these maintenance practices, you can extend the lifespan of your oil cooler and prevent costly repairs.

Common problems with poorly maintained or incorrectly installed oil coolers may include overheating, reduced lubrication efficiency, or even engine damage. If facing issues such as inadequate cooling or leaking fluids, it is recommended to consult a professional mechanic for diagnosis and repair.

Addressing problems promptly not only protects your engine but also ensures that your vehicle operates at peak performance levels. Remember that preventive measures through regular maintenance go a long way in avoiding major malfunctions with your car engine oil cooler system.

Signs of Oil Cooler Malfunction.

Recognizing the signs of an oil cooler malfunction is crucial for maintaining the health of your vehicle’s engine. One key symptom to watch out for is abnormal engine temperatures. If you notice that your engine temperature gauge is consistently running higher than normal or fluctuating erratically, it could indicate a potential issue with the oil cooler.

Another red flag to be aware of is decreased performance, such as reduced power output or sluggish acceleration, which may stem from inadequate cooling of the engine oil due to a faulty cooler.

Diagnosing specific problems associated with oil cooler malfunctions involves identifying common issues like clogs, leaks, or faulty components within the cooling system. A clog in the oil cooler can restrict the flow of oil and hinder proper cooling efficiency, leading to overheating concerns.

Leaks in the oil cooler lines or connections can result in a loss of oil pressure and lubrication function, potentially causing significant damage to engine components over time. Moreover, faulty components like a malfunctioning thermostat can disrupt the regulation of oil temperature within the system, affecting overall engine performance.

Timely detection and repair of oil cooler malfunctions are paramount to prevent further damage to the engine. Ignoring warning signs or postponing necessary maintenance can escalate minor issues into major problems that may require costly repairs or even engine replacement.

Regular inspection and proactive monitoring of your vehicle’s cooling system can help catch potential malfunctions early on, allowing for prompt intervention before severe consequences arise. By addressing oil cooler issues promptly, you not only safeguard your engine’s longevity but also ensure continued optimal performance and efficiency.

Efficiency Improvements through Upgraded Oil Cooling Systems.

Upgrading oil cooling systems in vehicles can significantly enhance overall performance and engine longevity. Introducing advanced technologies like thermostatic control valves allows for precise temperature regulation, ensuring that the oil stays within the optimal operating range.

By controlling when the oil cooler activates based on temperature, these valves help optimize cooling efficiency while reducing unnecessary workload on the system. Such upgrades contribute to maintaining consistent lubrication properties and improving the engine’s overall health.

Discussing aftermarket solutions for enhancing cooling capacity without compromising reliability is crucial for auto enthusiasts seeking to maximize their vehicle’s potential. Aftermarket coolers often offer increased surface area for heat dissipation, faster coolant flow rates, and improved durability compared to stock components.

Products from reputable manufacturers provide reliable solutions tailored to specific vehicle models, promoting efficient oil cooling under varying operating conditions. Exploring these aftermarket options allows automotive enthusiasts to tailor their oil cooling setups to meet specific performance requirements without sacrificing reliability.

Addressing concerns related to compatibility with different vehicle models when considering upgrades is essential for ensuring seamless integration and functionality. While universal oil cooling kits may offer versatility, they may not always provide an exact fit or optimal performance for every vehicle type.

Understanding the compatibility nuances ensures that the upgraded oil cooling system aligns with the engine specifications and operating conditions of a particular vehicle model. By selecting components designed specifically for compatibility with a given make and model, enthusiasts can maximize the benefits of their enhanced oil cooling setup effectively.

Enhancing oil cooling systems through advanced technologies and aftermarket solutions offers auto enthusiasts opportunities to improve their vehicles’ thermal management capabilities efficiently.

By carefully selecting compatible upgrades and incorporating state-of-the-art components into the existing system, individuals can achieve superior heat dissipation, maintain optimal oil temperatures, and prolong engine life effectively.

Prioritizing compatibility, reliability, and performance when upgrading oil coolers equips enthusiasts with tailored solutions that enhance overall driving experience while safeguarding engine health in various automotive applications.

How does an engine oil cooler differ from a car radiator?

While both are heat exchangers, engine oil coolers and car radiators serve different purposes:

Purpose.

- Radiator: Cools the engine coolant to prevent the engine from overheating.

- Oil Cooler: Cools the engine oil to maintain optimal viscosity and prevent oil breakdown.

Fluid Circulated.

- Radiator: Circulates the engine coolant.

- Oil Cooler: Circulates the engine oil.

Location.

- Radiator: Located at the front of the vehicle to dissipate heat from the coolant.

- Oil Cooler: Typically located near the engine or transmission to cool the oil.

Importance.

- Radiator: Critical for preventing engine overheating and damage.

- Oil Cooler: Enhances engine performance and longevity, but not as critical as the radiator.

So in summary, the radiator and oil cooler work together to keep the engine operating at optimal temperatures, but they serve distinct functions in the cooling system.

Are engine oil coolers necessary for all types of cars?

Necessity of engine oil coolers.

No, engine oil coolers are not necessary for all types of cars. The need for an oil cooler depends on several factors:

Engine Type.

- High-performance, high-revving engines (e.g. sports cars, race cars) tend to benefit more from oil coolers.

- Standard passenger vehicles with less demanding engines may not require an oil cooler.

Driving Conditions.

- Vehicles used for towing, hauling, or frequent high-speed driving generate more heat and may need an oil cooler.

- Mild driving conditions in temperate climates may not necessitate an oil cooler.

Climate.

- Vehicles operated in hot, arid climates are more likely to benefit from an oil cooler.

- Cooler climates may not require an oil cooler to maintain optimal oil temperatures.

Manufacturer Recommendations.

- Some automakers may recommend or require an oil cooler, especially for high-performance models.

- Standard models may not come equipped with an oil cooler from the factory.

So in general, engine oil coolers are more essential for high-performance, high-heat applications, while they may be optional or unnecessary for more basic passenger vehicles.

What are the main benefits of using an engine oil cooler?

Installing an engine oil cooler can provide several important benefits:

Improved Engine Cooling.

- Helps maintain optimal oil temperature to prevent overheating and oil breakdown.

- Enhances overall engine cooling and performance.

Maintained Oil Viscosity.

- Keeps the oil at the proper viscosity for effective lubrication.

- Prevents the oil from thinning out at high temperatures.

Extended Oil Life.

- Reduces the rate of oil degradation and oxidation.

- Helps the oil last longer before needing to be changed.

Reduced Engine Wear.

- Proper oil temperature and viscosity minimizes friction and wear on engine components.

- Extends the overall lifespan of the engine.

Better Fuel Efficiency.

- Improved oil flow and reduced friction can lead to slight gains in fuel economy.

Enhanced Performance.

- Maintains optimal oil pressure and flow for high-performance engines.

- Allows the engine to operate at peak efficiency.

So in many cases, adding an engine oil cooler can be a worthwhile investment to protect the engine and improve overall vehicle performance and longevity.

Conclusion: Understanding the Vitality of Car Engine Oil Coolers.

In reviewing various case studies showcasing the successful integration of tailor-made oil cooling solutions in high-performance vehicles, we have observed tangible evidence supporting the pivotal role of car engine oil coolers in optimizing engine functionality.

The empirical data presented underlines the substantial improvements in engine performance and durability upon implementing specialized oil cooler configurations tailored to specific automotive requirements.

These real-life applications reinforce the notion that a well-designed and efficiently maintained oil cooling system is not merely a luxury but an indispensable component for safeguarding engine health and overall vehicle longevity.

In conclusion, this comprehensive exploration into the realm of car engine oil coolers affirms their irreplaceable significance in ensuring optimal engine temperature regulation and lubrication efficiency.

By summarizing key insights from our investigation, we emphasize the imperative nature of meticulous installation, routine maintenance practices, and vigilant monitoring to uphold peak operational performance of these essential cooling mechanisms.

As automotive enthusiasts, mechanics, and engineering students delve deeper into understanding the intricacies of oil cooler functionalities, embracing best practices in managing these systems will undoubtedly fortify their prowess in maintaining and enhancing automotive performance standards across diverse vehicular platforms.