Demystifying the Car Engine Brake Hose

The intricate dance of components within an automobile that ensures its safe operation often goes unnoticed, yet each part plays a crucial role. Among these vital elements, the car engine brake hose stands as a silent sentinel, quietly transferring hydraulic force to bring your vehicle to a halt when needed. This unsung hero operates seamlessly within the complex braking system, ensuring precision and reliability in every stop.

Merging engineering prowess with functionality, the car engine brake hose acts as a conduit for hydraulic brake fluid, executing the critical task of transmitting pressure from the master cylinder to the wheel calipers. Its efficient operation is paramount for braking performance, underscoring its significance in guaranteeing driver and passenger safety on the open road.

As we delve deeper into demystifying the nuances of this humble component’s function and composition, a clearer understanding emerges of just how essential the brake hose is in maintaining optimal braking efficiency. Continued exploration will unravel the intricacies behind this unassuming yet indispensable link in your vehicle’s intricate chain of safety measures.

Unlocking its secrets promises not only enhanced expertise for auto enthusiasts and mechanics but also heightened awareness for drivers seeking to comprehend their vehicles at a deeper level. Join us on this journey as we navigate through the labyrinthine world of car engine brake hoses—a realm shrouded in technical brilliance waiting to be unveiled before you.

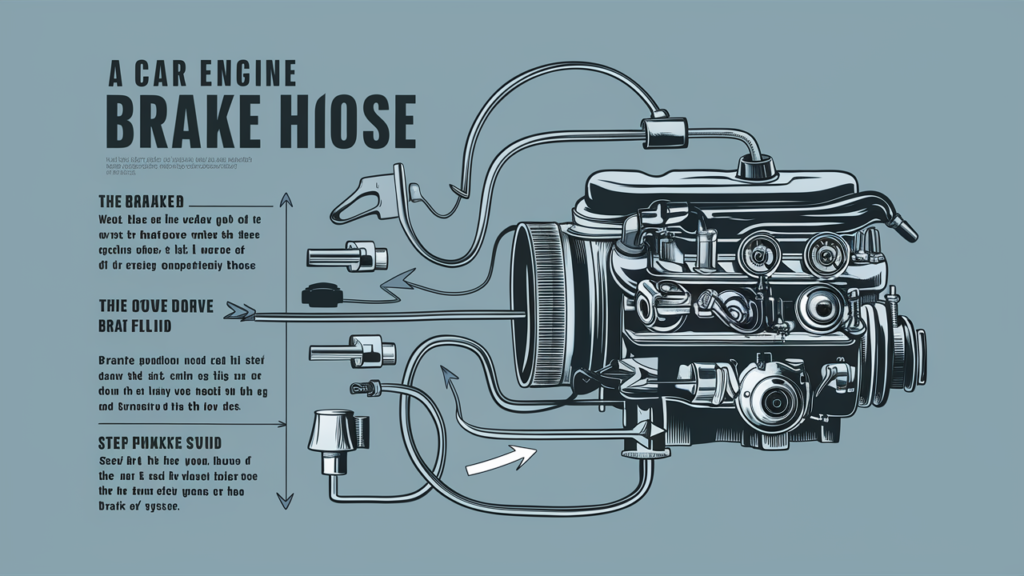

Understanding the Car Engine Brake Hose.

The car engine brake hose serves as a crucial component within an automobile’s braking system, responsible for transferring hydraulic brake fluid from the master cylinder to the wheel calipers.

This transmission of fluid is essential for converting the pressure generated when the driver depresses the brake pedal into mechanical force that stops the vehicle. By connecting vital components of the braking system, such as the master cylinder and wheel calipers, the brake hose ensures proper distribution of hydraulic pressure for efficient braking performance.

Manufacturers commonly use materials like rubber, stainless steel, or braided materials to construct brake hoses tailored for different types of vehicles. Rubber hoses offer flexibility and cost-effectiveness, making them ideal for everyday driving conditions.

In contrast, stainless steel and braided hoses are preferred in high-performance vehicles due to their enhanced durability and resistance to abrasion and heat. Regular inspection and maintenance of these brake hoses are imperative to prevent potential leaks, ruptures, or loss of braking efficiency while on the road.

To ensure safe driving conditions, drivers should prioritize inspecting their car engine brake hoses regularly. Visual checks for signs of wear, cracking, bulging, or corrosion can help identify potential issues before they escalate into safety hazards.

Timely maintenance tasks such as replacing worn-out hoses or tightening connections can not only prolong the lifespan of the brake system but also guarantee optimal performance during sudden braking situations. By understanding the role and materials used in manufacturing brake hoses and committing to routine inspections and upkeep measures, drivers can uphold safer driving practices on the road.

Components of a Car Engine Brake Hose.

When dissecting the anatomy of a car engine brake hose, it reveals an intricate design optimized for hydraulic functionality. The main components include an inner tube, reinforcement layer, and outer cover. The inner tube, typically made of rubber or synthetic materials, serves as the conduit for hydraulic fluid transmission.

Surrounding this tube is the reinforcement layer, crucial for withstanding the high pressures generated during braking. This layer can consist of braided steel wire or fabric to provide strength and resilience against bursting. Finally, the outer cover protects the hose from external elements like moisture and abrasion.

Structural integrity is paramount in brake hoses due to their role in managing hydraulic pressures within the braking system. The materials used in their construction must possess high tensile strength and resistance to corrosion to ensure reliable performance under duress.

Brake hoses are subjected to immense pressure fluctuations during vehicle operation, necessitating durability beyond everyday wear and tear. Rubber hoses are cost-effective but may degrade over time, while stainless steel options offer superior longevity but at a higher price point.

Braided hoses strike a balance between strength and flexibility, making them popular among drivers seeking reliability without compromising agility.

In comparing rubber, stainless steel, and braided hoses commonly found in cars, each material presents distinctive advantages based on specific driving needs. Rubber hoses excel in affordability but may require more frequent replacements compared to their stainless steel counterparts known for longevity and robustness against internal pressures.

Braided hoses merge the best of both worlds by incorporating durable materials within a flexible structure ideal for high-performance vehicles where precision braking is non-negotiable. Understanding these differences empowers drivers to align their choice of brake hose with driving habits and maintenance preferences for optimal safety on the road.

Functionality and Operation.

The car engine brake hose serves a critical role in the safe operation of a vehicle’s braking system by transmitting hydraulic pressure generated in the master cylinder to the wheel calipers. This transmission of pressure enables the activation of the brake pads against the rotors, subsequently slowing down or stopping the vehicle.

The hose acts as a conduit for hydraulic fluid under immense pressure, ensuring precise control over braking actions. For instance, when a driver depresses the brake pedal, this pressure is transmitted through the brake hose to engage the brakes at each wheel effectively.

Temperature fluctuations can significantly impact the flexibility and durability of brake hoses during operation. Extreme heat can cause rubber hoses to degrade prematurely, leading to cracks or leaks that compromise their structural integrity.

On the other hand, cold temperatures may make hoses more rigid, affecting their ability to flex and transmit hydraulic pressure efficiently. Selecting a high-quality brake hose becomes essential to mitigate these risks; durable materials like stainless steel or braided hoses offer enhanced resistance to temperature changes and external elements, ensuring reliable performance over an extended period.

Choosing a high-quality brake hose is paramount in preventing leaks or bursts under pressure that could jeopardize driving safety. A burst brake hose can result in a sudden loss of braking power, posing severe hazards on the road.

By investing in a reputable brake hose known for its durability and resilience to temperature variations, drivers can have peace of mind knowing that their brakes will function reliably under varying conditions. Regular inspection and maintenance also play a crucial role in identifying potential issues early on and addressing them promptly to prevent any safety risks associated with faulty brake hoses.

Inspection and maintenance.

Inspection and maintenance are critical aspects of ensuring the proper functioning of a car engine brake hose. To begin the inspection process, start by visually examining the brake hose for any signs of wear, corrosion, or damage. Look out for bulges, cracks, leaks, or fraying along the hose’s surface.

Additionally, check for any visible signs of abrasion caused by contact with other components. Ensuring that the brake hose is free from these issues is essential for maintaining optimal braking performance.

When determining when to replace a brake hose, it is important to consider both mileage and visible degradation indicators. As a general guideline, most manufacturers recommend replacing brake hoses every 4 to 6 years or between 60,000 to 100,000 miles, depending on driving conditions.

However, if you notice any of the aforementioned visible signs of damage during inspection or experience decreased braking responsiveness, it is advisable to replace the brake hose promptly to prevent potential safety hazards.

Proper installation and bleeding procedures during brake hose replacement are crucial steps in maintaining the integrity of the braking system. Ensure that all connections are secure and properly tightened to prevent leaks. When bleeding the brakes after installing a new hose, follow the manufacturer’s recommendations to remove any air bubbles from the system effectively.

Keep in mind that proper bleeding helps maintain consistent brake pedal feel and responsiveness. By adhering to these guidelines during inspection and maintenance tasks related to car engine brake hoses, drivers can ensure their safety on the road while prolonging the lifespan of their braking system.

Taking these proactive measures not only enhances safety but also contributes towards extending the longevity of your vehicle’s braking components. By following a systematic approach to inspecting and maintaining car engine brake hoses—including timely replacements based on wear indicators—you can uphold peak performance levels in your vehicle’s braking system.

Additionally, paying attention to proper installation techniques and post-replacement bleeding ensures that your brakes operate efficiently when you need them most—fostering a safe driving environment for you and those sharing the road with you.

Choosing the Right Brake Hose for Your Vehicle.

When choosing a replacement brake hose for your vehicle, it’s crucial to consider various factors that can impact performance and safety. Begin by identifying the make, model, and year of your car since brake hoses are not universal and must fit specific models to function effectively.

Whether you drive a compact sedan or a high-performance sports car, selecting the correct brake hose tailored to your vehicle is paramount.

When faced with the decision between aftermarket options and OEM brake hoses, understanding their differences is key. Original Equipment Manufacturer hoses are designed to meet the exact specifications of your vehicle, ensuring compatibility and reliability.

On the other hand, aftermarket brake hoses may offer customization options or performance enhancements but could potentially lack the precise engineering of OEM parts. It’s essential to weigh these factors against each other based on your driving habits and expectations.

Considering an upgrade to performance-oriented brake hoses can enhance your vehicle’s braking capabilities under demanding conditions. Performance brake hoses often feature reinforced materials or advanced designs that improve braking responsiveness and durability.

While these upgrades can provide benefits like reduced brake fade during aggressive driving maneuvers, they may come at a higher cost compared to standard replacements. Understanding the advantages and disadvantages of opting for performance-oriented brake hoses will help you make an informed decision based on your driving needs and budget constraints.

Safety Precautions When Dealing with Brake Hoses.

When it comes to handling brake hoses in your vehicle’s braking system, safety should be a top priority. Always adhere to safety protocols when working with hydraulic fluids or replacing a car engine brake hose.

Before beginning any maintenance tasks related to the brakes, it is crucial to ensure that the vehicle is securely supported on jack stands and that the emergency brake is engaged. Additionally, make sure the area is well-ventilated as brake fluid can emit harmful vapors.

Protective gear such as gloves and goggles must be worn while handling brake components. Hydraulic fluids are corrosive and can cause skin irritation upon contact, emphasizing the necessity for proper protective equipment.

Moreover, wearing goggles safeguards your eyes from potential splashes of brake fluid during maintenance procedures. By taking these precautions, you not only prioritize your safety but also promote responsible maintenance practices.

Neglecting faulty brake hoses while driving can lead to severe consequences. A leaking or ruptured brake hose compromises the hydraulic pressure needed for effective braking, resulting in diminished stopping power and increased stopping distances.

Imagine navigating a steep descent only to realize your brakes are failing due to neglected brake hoses—that scenario underscores the critical importance of regularly inspecting and maintaining these vital components to ensure optimal safety on the road.

Remember that proactive maintenance not only preserves your vehicle but also safeguards you and other road users from preventable accidents.

Recommended Practices for Extending Brake Hose Lifespan.

In conclusion, to ensure the longevity and optimal functionality of your car engine brake hose, it is crucial to adhere to recommended practices that prevent premature wear and maintain its integrity. Proper care and handling measures play a significant role in preserving the brake hose’s performance.

Avoiding kinks, sharp bends, or exposure to hot surfaces are essential steps to prevent damage that could compromise the brake hose’s structural integrity. By proactively implementing these preventive measures, drivers can mitigate the risk of accidents due to brake system failures caused by deteriorated hoses.

In this comprehensive guide on demystifying car engine brake hoses, we have explored the fundamental aspects of brake hose function, components, maintenance guidelines, and safety precautions.

By understanding the critical role that brake hoses play in a vehicle’s braking system and following best practices for care and maintenance, auto enthusiasts, mechanics, drivers, and automotive students can enhance driving safety and prolong the lifespan of their brake hoses.

Remember always to prioritize safety when dealing with hydraulic systems like brake hoses and apply these actionable recommendations consistently to promote a secure driving experience on the road.