Exploring the Functionality of a Car Engine Crankshaft

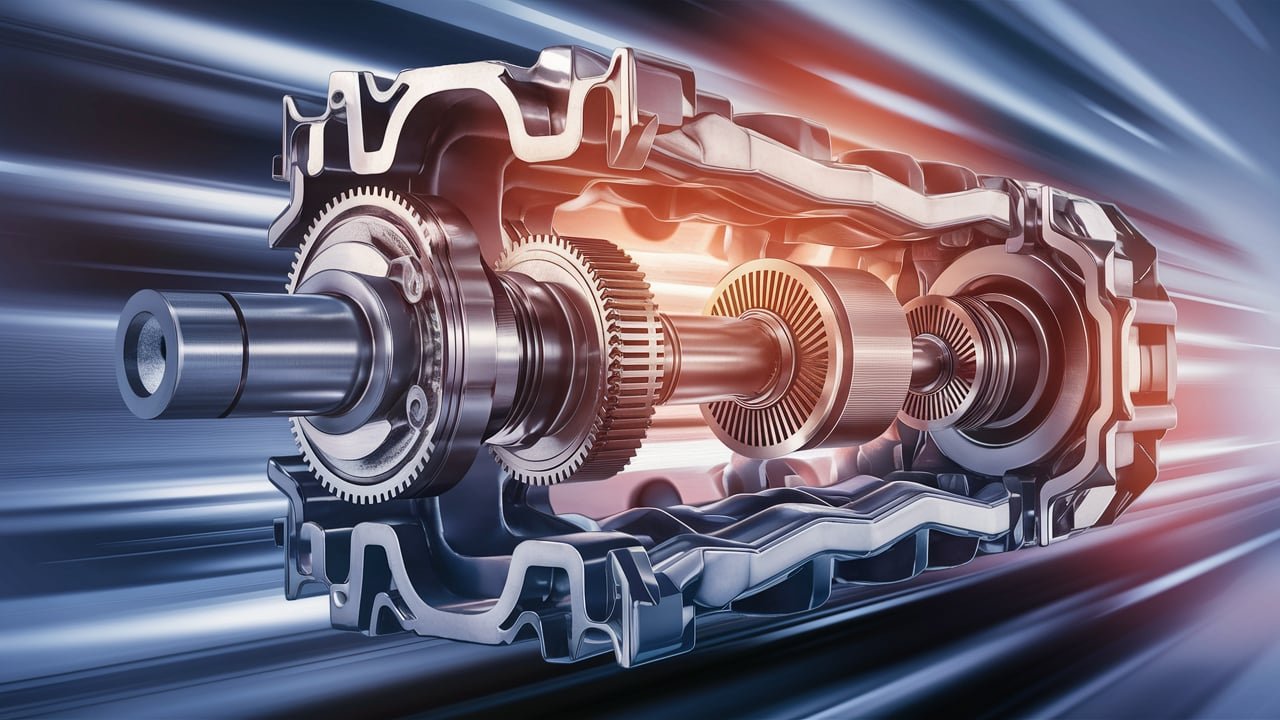

A car engine crankshaft is a critical component that converts the linear motion of pistons into rotary motion, ultimately driving the vehicle forward. Here’s a detailed explanation of its function and components:

Function.

The crankshaft is responsible for converting the vertical movement of pistons into horizontal rotational movement, which is then transmitted to the wheels through the gearbox. This process ensures that the vehicle can move forward.

Components.

The crankshaft consists of several key parts:

Main Journal: Supports the crankshaft’s rotation, mounted directly on the engine block.

Crankpins or Rod Journals: Connect to the pistons’ connecting rods, converting linear piston motion into rotational motion. Counterweights: Strategically placed along the crankshaft to reduce vibrations and ensure smooth operation. Thrust Washers: Help maintain proper alignment and balance. Main Oil Seals: Prevent oil leakage and ensure proper lubrication.

Working Principle.

The crankshaft’s working principle is based on the crank mechanism. It features journals that rotate inside bearings, with main bearing journals providing the axis of rotation and connecting rod journals moving the pistons through connecting rods. The distance between the center of the main journal and the crankshaft pin is called the crank radius, which determines the piston stroke.

Types.

Crankshafts come in different designs and materials to suit various engine configurations and vehicle types:

- Cast Cranks: Commonly found in in-line four engines, often flame hardened for wear resistance.

Forged Cranks: Used in some 16V engines, offering high clamping force. Billet Cranks: Have the lowest machining time and require minimal balancing.

Importance.

A well-balanced crankshaft ensures minimal vibrations, leading to smoother engine operation and better fuel efficiency. It plays a crucial role in the engine’s overall performance, interacting seamlessly with other engine parts like pistons and connecting rods.

Symptoms of Damage.

Common indicators of crankshaft damage include:

- Unusual Vibrations: Excessive vibrations from the engine, often accompanied by unusual sounds.

Engine Misfires: Disruptions in the engine’s firing sequence, leading to misfires and reduced power. Oil Leaks: Oil leaks near the front of the vehicle, indicating potential damage to the crankshaft or its components.

The crankshaft is a vital component of a car engine, responsible for converting linear piston motion into rotary motion. Its design and balance are critical to ensuring smooth engine operation, better fuel efficiency, and optimal performance. Recognizing the symptoms of crankshaft damage early on can prevent more extensive damage and costly repairs.

In the intricate symphony of automotive engineering, the car engine crankshaft stands as a silent conductor orchestrating the conversion of linear power into the rotational force that propels our vehicles forward.

This unassuming yet pivotal component lies at the heart of internal combustion engines, harmonizing the reciprocating motion of pistons into continuous rotation, a feat that embodies both precision and mechanical finesse. The depth of its functionality mirrors a ballet of engineering artistry, demanding an understanding that transcends mere mechanics.

Delving into the realm of automotive intricacies unveils an appreciation for the profound importance of comprehending every nuance of a crankshaft’s operation. As pillars in the realm of automotive craftsmanship, mechanics, automotive enthusiasts, and aspiring engineering minds alike are beckoned to decipher this enigmatic device that silently powers their machines forward.

By unraveling the secrets held within this spinning mastodon of vehicular vigor, a cascade of revelations unfolds—each revelation casting light on why mastery over this deceptively simple yet profoundly impactful mechanism heralds paramount significance in the realm of automotive innovation.

Let us embark on a voyage through gears, shafts, and revolutions to uncover the mesmerizing functionality weaving its magic within engine blocks around the world.

Functionality of a Car Engine Crankshaft.

The car engine crankshaft stands as the backbone of an internal combustion engine, converting the up-and-down motion produced by the pistons into rotational force that drives the vehicle.

Essentially, it serves as the connector between the reciprocating motion of the pistons and the smooth rotation required for propelling a vehicle forward. Through a complex mechanical process, the linear movement from each piston’s stroke is harnessed and transformed into consistent rotational energy to power various components of a car.

To understand how this engineering marvel achieves such function, we delve into its intricate design and components. A typical crankshaft comprises main journals, rod journals, counterweights, and connecting rod throws—all meticulously arranged to balance forces and vibrations generated during operation.

The precision in crafting these parts ensures minimal friction and maximum efficiency in power transmission. By strategically placing counterweights along its length, the crankshaft minimizes vibrations and maintains stability during high-speed rotations.

In observing how a crankshaft converts linear motion to rotational force, envision each piston’s downward thrust turning the throw of its connecting rod—connected to a specific point on the rotating crankshaft.

As one piston moves down (power stroke), another moves up (exhaust/intake cycle), creating a continuous push-pull effect that incrementally rotates the shaft on its axis.

This rotational output is then transmitted through various drive mechanisms within an automobile, culminating in propelling motion—the essence of a car’s forward movement driven by this ingenious mechanism inherent in every internal combustion engine.

Types of Car Engine Crankshafts.

In the realm of automotive engineering, the choice of material for a car engine crankshaft plays a significant role in determining its efficiency and durability. Modern vehicles commonly employ three main types of crankshaft materials: cast iron, forged steel, and billet steel. Cast iron crankshafts are traditionally known for their low-cost production and adequate performance in standard driving conditions.

However, they are heavier compared to their steel counterparts, which can affect overall engine weight and performance. Forged steel crankshafts, on the other hand, offer superior strength and fatigue resistance due to their manufacturing process that involves shaping under extreme pressure. This makes them ideal for high-performance engines where durability is crucial.

When comparing cast iron and forged steel crankshafts, it becomes evident that material selection directly impacts not only the strength but also the weight distribution within an engine. The lighter weight of forged steel crankshafts allows for reduced inertia forces during engine operation, leading to improved throttle response and overall performance efficiency.

On the contrary, cast iron crankshafts are more prone to flexing under high loads due to their heavier nature. In contrast, billet steel crankshafts represent a premium option characterized by their exceptional strength and precise machining capabilities. These crankshafts are often used in racing engines where every component’s quality is paramount to achieving optimal performance.

The choice between these different types of car engine crankshafts ultimately depends on factors such as desired engine output, budget constraints, and intended application. Cast iron may suffice for everyday commuting vehicles seeking reliability at a lower cost, while forged or billet steel options cater to enthusiasts craving enhanced performance and longevity from their engines.

Engineers carefully consider these attributes when designing new vehicles or upgrading existing ones to ensure the chosen crankshaft material aligns with the engine’s intended use case.

By understanding how material selection influences performance characteristics like weight, strength, and durability in a car engine’s crankshaft, automotive professionals can make informed decisions that optimize overall efficiency and reliability in vehicle operation.

Crankshaft Manufacturing Process.

The manufacturing process of a car engine crankshaft involves several intricate steps to ensure the production of a durable and high-performance component. To begin, the raw material, whether it be cast iron, forged steel, or billet steel, undergoes precision machining to shape it into the desired form of the crankshaft.

Machining processes like turning, milling, and grinding are employed to achieve the precise dimensions and surface finishes required for optimal functionality within an engine.

Precision machining techniques play a vital role in enhancing the reliability and longevity of a crankshaft. By ensuring that every contour and dimension of the crankshaft meets exact specifications, manufacturers can minimize structural weaknesses that could lead to premature wear or failure.

For instance, the critical journals where bearings are mounted must be machined with extreme accuracy to guarantee smooth rotation within the engine block and proper lubrication flow.

Quality control measures are paramount during crankshaft production to uphold structural integrity and performance standards. Inspections at various stages of manufacturing assess factors such as dimensional accuracy, geometric alignment, surface finish quality, and material composition.

Non-destructive testing methods like X-ray inspection or ultrasonic testing help detect internal defects that could compromise the crankshaft’s strength. By adhering to stringent quality control protocols, manufacturers can deliver crankshafts that meet rigorous industry requirements for safety and efficiency.

In essence, from selecting the appropriate material to utilizing advanced machining techniques and quality assurance procedures, each phase of the crankshaft manufacturing process contributes to producing a reliable component vital for powering automotive engines.

The attention to detail in every step underscores the commitment to excellence necessary in creating components that endure harsh operating conditions while delivering consistent performance over extended periods.

Signs of Crankshaft Wear and Failure.

Crankshafts, while durable components in an engine, are not immune to wear and potential failure. Mechanics and enthusiasts should be vigilant for common signs that signal issues with the crankshaft to prevent severe consequences.

One prevalent indicator of crankshaft wear is increased engine vibration that resonates through the vehicle when running. This vibration can escalate if left unattended, leading to more significant problems within the engine’s internal components.

Another concerning symptom of crankshaft problems is the appearance of metallic noises or knocking sounds emanating from the engine bay during operation. These sounds often indicate bearing wear due to poor lubrication, which can ultimately cause catastrophic failures if ignored.

Additionally, oil leaks around the front or rear seals of the engine could suggest seal deterioration attributed to crankshaft misalignment or excessive movement. Addressing these issues promptly is crucial to avoid costly repairs or a complete engine breakdown.

Regular inspection and maintenance practices are essential in preventing severe consequences associated with crankshaft wear and potential failures. Mechanics and enthusiasts should prioritize timely oil changes using high-quality lubricants that ensure proper lubrication of bearings along the crankshaft.

Furthermore, conducting routine checks on alignment and balance ensures that the crankshaft operates smoothly without placing undue stress on adjacent engine components. By proactively addressing warning signs and adhering to recommended maintenance schedules, individuals can prolong the lifespan of their car’s crankshaft while maximizing overall performance and safety on the road.

Importance of Regular Maintenance for Crankshafts.

Regular maintenance of a car engine’s crankshaft is paramount in ensuring optimal performance and longevity of the entire engine system. By adhering to a structured maintenance schedule, mechanics and automotive enthusiasts can significantly extend the lifespan of the crankshaft, which plays a crucial role in converting linear motion into rotational power.

Routine maintenance tasks, such as lubrication, inspection, and alignment checks, are essential in detecting early signs of wear or misalignment that could lead to more severe issues if left unaddressed.

Lubrication is especially critical for the smooth operation of the crankshaft components. Proper lubrication helps reduce friction between moving parts, preventing excessive wear and heat buildup that could cause premature failure.

Regularly inspecting the crankshaft for any signs of damage or misalignment allows mechanics to catch potential issues before they escalate, thus avoiding costly repairs or replacements down the line. Additionally, conducting alignment checks ensures that the crankshaft remains properly aligned with other engine components, maintaining efficient power transfer throughout the system.

The benefits of proactive maintenance strategies extend beyond just preventing unexpected downtime and costly repairs. When maintenance tasks are consistently performed on schedule, it not only prolongs the lifespan of the crankshaft but also contributes to overall engine reliability and efficiency.

For example, timely lubrication can help minimize wear on bearing surfaces, leading to smoother operation and enhanced fuel efficiency. Furthermore, by identifying and rectifying minor issues early through regular inspections, mechanics can prevent larger problems from developing that could potentially compromise engine safety or performance.

Ultimately, investing time and resources into regular maintenance for crankshafts is a preventive measure that pays dividends in terms of long-term engine health and functionality.

What are the common problems with a crankshaft position sensor?

A faulty crankshaft position sensor can cause several symptoms, including:

- Check Engine Light: The illumination of the check engine light on the dashboard is a common indicator of problems, including issues with the crankshaft position sensor.

- Engine Stall: A failing crankshaft position sensor may cause intermittent engine stalls, especially during idling or low-speed operation.

- Engine and Vehicle Shake Strongly: A malfunction can result in rough and uneven engine operation, causing the entire vehicle to shake noticeably.

- Misfire: Irregular readings from the crankshaft position sensor can lead to misfires in the engine, characterized by a lack of synchronization in the combustion process.

- Reduction in Engine Performance: A bad crankshaft position sensor can significantly impact engine performance, causing a reduction in power, acceleration, and overall responsiveness.

- Unable to Start the Car: In severe cases, a malfunctioning crankshaft position sensor may prevent the engine from starting altogether.

- Rapid Increase in Engine’s Resistance to Acceleration: An abrupt and significant increase in the engine’s resistance to acceleration, especially during throttle input, can be indicative of a crankshaft position sensor issue.

- Poor Mileage: Due to compromised engine timing and combustion efficiency, a failing crankshaft position sensor can contribute to decreased fuel efficiency, resulting in poor mileage.

How does a crankshaft position sensor work?

A crankshaft position sensor measures the crankshaft’s speed and position. It is typically installed near the flywheel ring gear and uses either inductive sensors or Hall generators to detect the rotational movement of the ring gear. The sensor generates varying voltage signals based on the magnetic field changes, which are then transmitted to the control unit. The control unit uses these signals to calculate the speed and position of the crankshaft, providing important data for injection and ignition timing.

What is the difference between a camshaft and a crankshaft?

The terms “crankshaft sensor” and “camshaft sensor” are often used interchangeably, but there can be a subtle difference in their meanings. Crankshaft sensor is a broad term that encompasses any sensor that measures parameters related to the crankshaft. Crankshaft position sensor, on the other hand, specifically measures the position and speed of the crankshaft. Camshaft sensor, while not as commonly used, typically refers to sensors that measure the position and speed of the camshaft, which is responsible for opening and closing the engine’s valves.

Conclusion.

In conclusion, understanding the intricacies of a car engine crankshaft is fundamental for anyone involved in the automotive field, whether as a mechanic, an enthusiast, or an engineering student. The crankshaft serves as the backbone of an internal combustion engine, converting linear motion from pistons into rotational motion that drives the vehicle.

By delving into the functionality, types, manufacturing processes, and maintenance practices associated with this critical component, individuals can enhance their knowledge of how engines operate and develop essential skills for troubleshooting and upkeep.

By comprehensively exploring the function and characteristics of a car engine crankshaft through this article, readers have gained valuable insights into its role within the broader system of an automobile.

From differentiating between crankshaft materials to recognizing signs of wear and failure early on, this comprehensive guide aims to equip enthusiasts with the knowledge necessary to ensure optimal performance and longevity of their vehicles.

Ultimately, mastering the nuances of a car engine crankshaft not only enhances one’s understanding of automotive engineering but also underscores the importance of meticulous maintenance practices in sustaining a vehicle’s reliability and efficiency over time.