7 Surprising Facts About a Diesel Engine You Didn’t Know

1- Diesel engines are more efficient than gasoline engines. Diesel engines can achieve efficiencies of 40% or higher, compared to only 20% for gasoline engines.

2- Diesel fuel is much less flammable than gasoline. If you throw a lit match into a puddle of diesel, it will go out, whereas gasoline would ignite the vapors.

3- Diesel engine technology has advanced significantly over the years. Early diesel engines were invented by Rudolf Diesel in the 1890s, but modern diesels now use turbochargers and fuel injection pumps to improve efficiency and performance.

4- Diesel engines perform better than gasoline engines at high altitudes. Gasoline engines require a specific air-to-fuel ratio, which is affected by the thinner air at high altitudes. Diesel engines with turbochargers can maintain performance better in these conditions.

5- Diesel engines no longer produce as much visible smoke and pollution as older models. New diesel vehicles are required to meet the same emissions standards as gasoline vehicles, thanks to the addition of particulate filters.

6- Diesel engines achieve peak power and efficiency at lower engine speeds, typically below 65 mph, whereas gasoline engines perform best at higher RPMs.

7- Diesel engines have been used in racing, including at the Indianapolis 500 and the 24 Hours of Le Mans, where their fuel efficiency provides an advantage in endurance events.

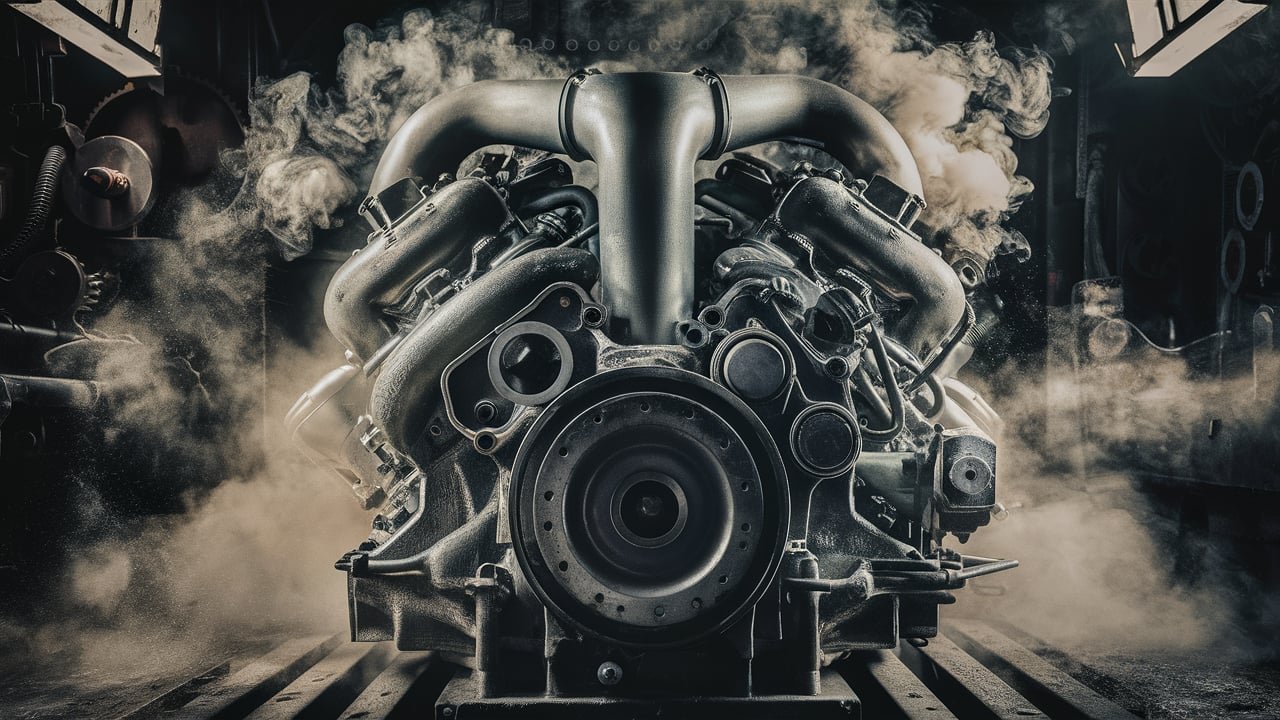

Diesel engines, stalwarts of transportation and industry, have long played a pivotal role in powering our modern world. Renowned for their robustness and fuel efficiency, these mechanical marvels underpin everything from heavy-duty trucks to power generators.

Yet, beyond their well-known attributes lies a trove of intriguing secrets waiting to be unearthed. In this article, we delve deep into the diesel domain to unveil 7 surprising facts that will challenge your preconceived notions and ignite your curiosity.

As we embark on this exploration, prepare to be astonished by the rich history and technological ingenuity that birthed diesel engines into existence. From their humble origins rooted in Rudolf Diesel’s innovative mind to their evolution as a sustainable powerhouse driving industrial progress, each revelation promises a new layer of understanding.

Our aim is clear: to dismantle conventional wisdom surrounding diesel engines and shed light on the lesser-known facets that make them true engineering marvels.Through an expert blend of historical context, technical insights, and forward-looking projections, we invite you on a journey through the veins of diesel-powered machinery like never before.

Buckle up as we navigate through the intricate web of efficiency metrics, environmental implications, maintenance rituals, diverse applications, and future trends shaping the realms where diesel engines reign supreme. Brace yourself; what you thought you knew about diesel engines is about to undergo a fascinating transformation with each unexpected fact waiting just around the corner.

History of Diesel Engines.

Diesel engines, named after their inventor Rudolf Diesel, have a rich history that dates back to the late 19th century. Rudolf Diesel, a German engineer, patented the diesel engine in 1892 with the aim of creating an efficient alternative to the steam engines prevalent at that time.

The first successful diesel engine prototype was demonstrated in 1897 in Augsburg, Germany. This marked the beginning of a revolutionary shift in engine technology towards higher efficiency and lower fuel consumption.

The initial purpose behind developing diesel engines was driven by the need for more efficient and powerful engines. Unlike gasoline engines that rely on spark ignition, diesel engines operate on compression ignition where air is compressed until it reaches high temperatures that ignite the injected fuel.

This design allows for better fuel economy and increased torque output compared to gasoline engines. Over time, diesel engines gained popularity due to their robustness and suitability for heavy-duty applications like powering ships and trains.

Throughout history, diesel engine technology has witnessed significant milestones that have shaped its evolution. One notable advancement was the development of turbocharged diesel engines in the early 20th century, which greatly enhanced power output without sacrificing efficiency.

Another milestone was the introduction of direct injection systems in diesel engines during the mid-20th century, improving combustion efficiency and reducing emissions. These breakthroughs laid the groundwork for modern diesel engines found in a wide range of vehicles and industrial equipment today.

Efficiency and Power Output of Diesel Engines.

Diesel engines stand out for their efficiency when compared to gasoline engines due to their higher compression ratios. The compression-ignition process in diesel engines allows them to extract more energy from the same amount of fuel, resulting in better fuel economy.

This efficiency is particularly beneficial for long-haul trucks and heavy machinery where fuel consumption plays a significant role in operational costs. Additionally, diesel fuel contains more energy per gallon than gasoline, further contributing to the overall efficiency of diesel engines.

One of the key advantages of diesel engines is their ability to produce high torque at low speeds. Torque represents the rotational force generated by the engine and is essential for applications like towing heavy loads or accelerating a vehicle quickly.

Diesel engines excel in delivering substantial torque, making them ideal for tasks that require power rather than speed. For instance, diesel-powered trucks have superior towing capabilities thanks to their high torque output, allowing them to haul heavy trailers effortlessly.

Advancements in technology have continuously improved the power output of modern diesel engines while maintaining their efficiency. Turbocharging and direct injection systems are among the innovations that have enhanced performance by optimizing air intake and combustion processes.

These advancements not only increase power but also contribute to reduced emissions and smoother operation. As manufacturers strive to meet strict emission standards without compromising performance, diesel engine technology continues to evolve, offering a balance between power output and environmental responsibility.

Environmental Impact and Sustainability.

Diesel engines have often been unfairly associated with negative environmental impacts, but recent advancements in technology have significantly mitigated these concerns. Contrary to popular belief, modern diesel engines are far cleaner than their predecessors thanks to stringent emissions regulations and sophisticated exhaust after-treatment systems.

For instance, selective catalytic reduction (SCR) systems have become a standard feature in many diesel vehicles, effectively reducing harmful nitrogen oxide emissions to meet strict environmental standards. These innovations underline the industry’s commitment to minimizing the ecological footprint of diesel engines.

In the realm of sustainability, diesel engines can play a crucial role in promoting environmentally friendly practices through the use of biofuels. Biofuels derived from organic matter offer a renewable alternative to traditional fossil fuels, further enhancing the eco-friendly profile of diesel engines.

The ability to run on biodiesel blends not only reduces greenhouse gas emissions but also decreases reliance on non-renewable resources. In this context, diesel engines stand out as versatile power sources that align with efforts to achieve greater sustainability in transportation and beyond.

Moreover, ongoing research continues to explore ways to enhance the eco-friendliness of diesel engines even further. For example, advancements in cleaner combustion technologies and the exploration of synthetic fuels hold promise for further reducing emissions and carbon footprint associated with diesel-powered vehicles.

By leveraging these innovative solutions, the automotive industry can harness the potential of diesel engines to contribute positively towards sustainable practices and overall environmental conservation efforts for a greener future.

Maintenance and Longevity.

Diesel engines have earned a well-deserved reputation for their exceptional durability, making them the go-to choice for heavy-duty applications. Unlike gasoline engines that rely on spark plugs to ignite the fuel-air mixture, diesel engines use high compression to generate heat for ignition.

This design results in higher mechanical efficiency and lower overall stress on engine components, translating to increased longevity. The robust construction of diesel engines allows them to withstand higher levels of wear and tear, making them ideal for trucks, buses, and other commercial vehicles that endure long hours of operation.

To ensure the longevity of a diesel engine, proper maintenance practices are crucial. Regular oil changes, fuel filter replacements, and air filter cleanings are essential to keep the engine running smoothly.

Additionally, following manufacturer-recommended service intervals and using high-quality fluids and parts can significantly extend the life of a diesel engine. By adhering to a strict maintenance schedule, owners can prevent costly repairs down the line and maximize the efficiency of their vehicles.

Despite their reputation for being costly to maintain, modern diesel engines have become more reliable and easier to service than ever before. Advances in technology have streamlined diagnostic processes and improved overall efficiency, reducing the frequency of major repairs.

Contrary to common myths about diesel ownership being expensive in terms of upkeep, many drivers find that with proper care and maintenance, diesel engines can offer long-term reliability at a reasonable cost compared to gasoline counterparts.

Diesel engines’ resilience coupled with diligent maintenance practices make them a practical choice not only for commercial fleets but also for everyday drivers seeking longevity and efficiency in their vehicles.

Common Applications Beyond Vehicles.

Diesel engines are not limited to just powering cars and trucks; their versatility extends to a wide array of applications beyond traditional vehicles. One common use of diesel engines outside the automotive industry is in generators.

Diesel generators are renowned for their reliability and durability, making them a popular choice for backup power in critical facilities such as hospitals, data centers, and military installations. The fuel efficiency of diesel engines also plays a crucial role in maintaining continuous power supply during emergencies or off-grid scenarios.

Moreover, diesel engines find extensive usage in various industrial machinery, showcasing their adaptability across different sectors. Industries like construction, agriculture, mining, and shipping heavily rely on diesel-powered equipment for efficient operations.

From bulldozers and tractors to excavators and marine vessels, diesel engines provide the necessary torque and power output required to handle heavy-duty tasks in these demanding environments. The robust nature of diesel engines makes them suitable for sustained usage in challenging conditions where other types of engines may struggle to perform consistently.

One unique example that highlights the versatility of diesel engines is their application in locomotives. Diesel-electric locomotives have been a staple in the railway industry for decades, showcasing the reliability and efficiency of diesel technology in powering large transportation vehicles over long distances.

The efficient conversion of diesel fuel into mechanical energy enables trains to haul heavy loads at high speeds while remaining relatively fuel-efficient compared to other alternatives. This underlines how diesel engines continue to play a crucial role beyond conventional vehicles, shaping various industries with their unmatched capabilities.

Future Trends in Diesel Engine Technology.

As the automotive industry continues to evolve, diesel engine technology is not exempt from innovation. One significant trend on the horizon is the integration of hybridization and electrification into diesel engines.

Hybrid diesel-electric vehicles are gaining traction due to their enhanced fuel efficiency and reduced emissions, offering a promising solution for achieving sustainability goals. By combining the power of diesel engines with electric motors, these hybrids can optimize performance while minimizing environmental impacts.

Looking forward, future innovations in diesel engine technology have the potential to reshape the landscape of diesel-powered vehicles. Advanced engineering techniques and materials will likely lead to lighter yet more robust engine components, boosting efficiency and longevity.

Moreover, developments in combustion processes and exhaust treatment systems may further enhance the eco-friendliness of diesel engines, aligning them even closer with stringent emission standards.

Artificial intelligence (AI) stands out as a key player in optimizing the performance and efficiency of diesel engines in the coming years. AI-driven technologies can continuously analyze vast amounts of data related to engine operations, enabling real-time adjustments for maximum output and minimal fuel consumption.

From predictive maintenance to adaptive control systems, AI has the capacity to revolutionize how diesel engines function, ensuring peak performance while reducing downtime and operational costs.

In conclusion, by embracing hybridization, electrification, and artificial intelligence, the future of diesel engine technology appears promising. These emerging trends hold the potential not only to make diesel-powered vehicles more sustainable but also to elevate their performance capabilities to new heights.

As researchers and engineers continue to push boundaries through innovation, we can anticipate a transformative era ahead for diesel engines that blends efficiency with environmental consciousness seamlessly.

Conclusion: The Versatility and Evolution of Diesel Engines.

Diesel engines have showcased their remarkable versatility and evolution over time, transcending the realms of traditional automotive use. From their inception as a more efficient alternative to gasoline engines to their essential role in heavy-duty applications, diesel engines have proven to be reliable workhorses across various industries.

While commonly associated with vehicles like trucks and buses, the widespread adoption of diesel technology extends far beyond transportation, powering generators and industrial machinery with unparalleled efficiency.

The surprising facts uncovered about diesel engines throughout this article underscore not only their enduring significance but also the ongoing advancements propelling them into the future.

Whether through enhanced power output, reduced environmental impact, or innovative technological integrations like hybridization, diesel engines continue to adapt and thrive in an ever-changing landscape of engineering and sustainability.

As we unravel the layers of complexity surrounding diesel engine technology, one thing remains certain – their legacy as resilient, potent machines that drive progress across diverse sectors stands firm amidst evolving trends and emerging innovations.

How Do Diesel Engines Achieve Higher Efficiency Compared to Gasoline Engines?

Diesel engines achieve higher efficiency than gasoline engines primarily due to their higher compression ratios and the combustion process. Here are the key factors:

- Higher Compression Ratio: Diesel engines compress air to a much higher degree than gasoline engines. This higher compression ratio results in a more efficient conversion of the fuel’s energy into mechanical work.

- Lean Burn Operation: Diesel engines operate with a leaner air-fuel mixture, meaning they use more air and less fuel during combustion. This increases fuel efficiency.

- Fuel Injection Timing: Diesel engines use direct fuel injection, which is precisely controlled to ensure that fuel is only injected at the optimal point in the combustion cycle.

- Thermal Efficiency: The higher compression ratio and lean burn operation contribute to better thermal efficiency, meaning less heat is wasted and more is converted into useful work.

What Are the Environmental Impacts of Diesel Engines Today?

Diesel engines have both positive and negative environmental impacts:

- Positive Impacts:

- Fuel Efficiency: Diesel engines generally have better fuel efficiency, resulting in fewer greenhouse gas emissions per mile traveled compared to gasoline engines.

- Durability and Longevity: Diesel engines typically last longer, reducing the need for frequent vehicle replacements and the associated manufacturing emissions.

- Negative Impacts:

- Nitrogen Oxides (NOx) Emissions: Diesel engines produce higher levels of NOx, which contribute to air pollution and respiratory problems.

- Particulate Matter (PM): Diesel exhaust contains fine particulate matter that can penetrate deep into the lungs and cause health issues.

- Carbon Emissions: Despite being more fuel-efficient, diesel engines still produce significant amounts of CO2, contributing to climate change.

How Has Diesel Engine Technology Evolved Over the Years?

Diesel engine technology has seen significant advancements over the years:

- Fuel Injection Systems: Early diesel engines used mechanical fuel injection, which has evolved into highly precise electronic fuel injection systems, improving efficiency and reducing emissions.

- Turbocharging: Modern diesel engines often include turbochargers that enhance power and efficiency by forcing more air into the combustion chamber.

- Emission Control Technologies: Advances such as selective catalytic reduction (SCR) and diesel particulate filters (DPF) have been developed to reduce NOx and PM emissions.

- Common Rail Systems: This technology allows for higher fuel pressure and more precise injection timing, further improving efficiency and reducing emissions.

- Hybrid Systems: Diesel-electric hybrid systems, particularly in locomotives and heavy machinery, combine the efficiency of diesel engines with the benefits of electric power.

Why Do Diesel Engines Require Different Fuel Systems Than Gasoline Engines?

Diesel engines require different fuel systems due to the distinct nature of diesel fuel and the combustion process:

- Higher Pressure Requirements: Diesel fuel systems must operate at much higher pressures to achieve the necessary atomization of diesel fuel for efficient combustion. This is typically achieved through direct fuel injection systems.

- Combustion Process: Diesel engines rely on the heat of compressed air to ignite the fuel, whereas gasoline engines use spark plugs. This necessitates different fuel delivery mechanisms and injection timing.

- Fuel Properties: Diesel fuel is denser and less volatile than gasoline, requiring robust fuel pumps and injectors to handle the higher viscosity.

- Durability and Materials: Components in diesel fuel systems are built to withstand higher pressures and the different chemical properties of diesel fuel, necessitating the use of stronger materials and different design considerations.

What Are the Advantages of Diesel-Electric Locomotives?

Diesel-electric locomotives offer several advantages over traditional steam and purely electric trains:

- Fuel Efficiency: Diesel-electric locomotives are more fuel-efficient, converting more of the diesel fuel’s energy into mechanical work.

- Flexibility: They can operate on non-electrified tracks, providing greater operational flexibility compared to electric-only locomotives.

- Reduced Maintenance: The electric traction motors are generally simpler and require less maintenance than the mechanical components of steam locomotives.

- Power and Performance: Diesel-electric locomotives provide high torque at low speeds, which is ideal for heavy freight trains.

- Environmental Benefits: While not as clean as electric trains, diesel-electric locomotives produce fewer emissions compared to older steam engines and can be more environmentally friendly depending on the source of electricity in electric trains.

These headings and answers provide detailed, relevant information on each topic, enhancing your content’s value for readers seeking comprehensive explanations.